|

|

|||

|

Privacy Policy | Editorial Policy | Profit Policy | Join the Association | List of Members | Contact us | Index | Links |

|||

|

Back Go to page: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Forward |

|||

|

Allan George’s Gems.

|

|||

|

|

|||

|

|

|||

|

Aerogel.

Aerogel is a synthetic porous ultralight material derived from a gel in which the liquid component of the gel has been replaced with a gas. They are the world's lightest solid materials, composed of up to 99.98% air by volume and as a result are a solid with extremely low density and low thermal conductivity. Nicknames include frozen smoke, solid smoke, solid air, or blue smoke owing to its translucent nature and the way light scatters in the material. They feel like fragile expanded polystyrene (Styrofoam) to the touch. Aerogels can be made from a variety of chemical compounds.

Aerogel was first created by Samuel Stephens Kistler in 1931 as a result of a bet over who could replace the liquid in "jellies" with gas without causing shrinkage. They are produced by extracting the liquid component of a gel through supercritical drying which allows the liquid to be slowly dried off without causing the solid matrix in the gel to collapse from capillary action, as would happen with conventional evaporation. The first aerogels were produced from silica gels. Kistler's later work involved aerogels based on alumina, chromia and tin dioxide. Carbon aerogels were first developed in the late 1980s.

In the pic at right, a flower is placed on a piece of aerogel which is suspended over a flame from a Bunsen burner. Aerogel has excellent insulating properties and the flower is protected from the flame. Despite their name, aerogels are solid, rigid, and dry materials that do not resemble a gel in their physical properties, the name only comes from the fact that they are made from gels. Pressing softly on an aerogel typically does not leave even a minor mark but pressing more firmly will leave a permanent depression. Pressing extremely firmly will cause a catastrophic breakdown in the sparse structure, causing it to shatter like glass – a property known as friability; although more modern variations do not suffer from this. Despite the fact that it is prone to shattering, it is very strong structurally. Its impressive load bearing abilities are due to the dendritic microstructure, in which spherical particles of average size (2–5 nm) are fused together into clusters.

Aerogels are good thermal insulators because they almost nullify two of the three methods of heat transfer (convection, conduction, and radiation). They are good conductive insulators because they are composed almost entirely from a gas and gases are very poor heat conductors. Silica aerogel is especially good because silica is also a poor conductor of heat (a metallic aerogel, on the other hand, would be less effective). They are good convective inhibitors because air cannot circulate through the lattice. Aerogels are poor radiative insulators because infrared radiation (which transfers heat) passes right through silica aerogel.

So what can you do with it??

In their earliest days, aerogels were marketed as thickening agents and used in everything from makeup and paint to napalm. They were also used as cigarette filters and insulation for freezers.

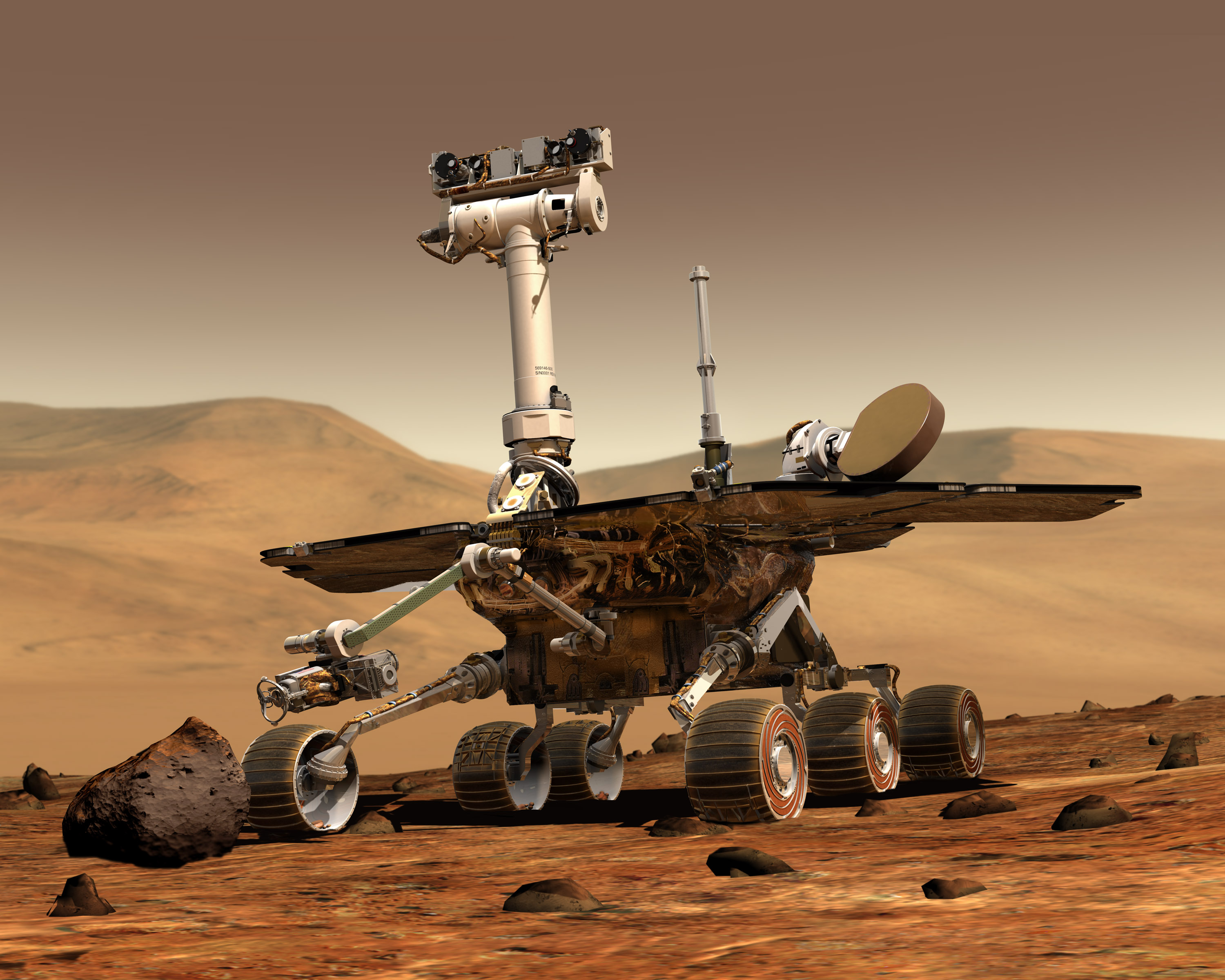

Not long ago scientists developed a process that made the production of

aerogels less toxic by using a safer alkoxide compound. They also made

it less dangerous by replacing supercritical alcohol with supercritical

carbon dioxide in the drying process. These developments reduced the

time spent drying the aerogels and reduced the hazardous and flammable

nature of their production. As aerogel's production was made less

complicated and dangerous, its unique properties have made aerogel

popular with a range of industries. Silicon manufacturers, homebuilding

materials manufacturers and space agencies (they were used in the Mars

lander) have all put aerogel to use. Its popularity has only been

hindered by cost, though there is an increasingly successful push to

create aerogels that are cost

Wetsuits. Fire-fighter suits. Skylights. Windows. Rockets. Paints. Cosmetics. Nuclear weapons.

Because of aerogel's unique structure, its use as an insulator is a no-brainer and companies are racing to find a way to bring production costs down, but for now, aerogels are more affordable for NASA than the general public. Perhaps when it's more affordable, aerogel will achieve that A-list status.

From Earth to space, and everywhere in between, aerogels undoubtedly have a place in our future.

|

|||

|

|

|||

|

Busy??

Want to know how to keep elderly people amused and busy for hours?? - get them to click HERE |

|||

|

|

|||

|

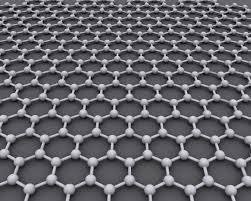

Graphene.

In simple terms, graphene is a thin layer of pure carbon; it is a

single, tightly packed layer of carbon atoms that are bonded together in

a hexagonal honeycomb lattice. It is the thinnest compound known to man

at one atom thick, the lightest material known, the strongest compound

discovered so far, between 100-300 times stronger than steel, the best

conductor of heat at room temperature and also the best conductor of

electricity known (so far). Carbon is the second most abundant mass

within the human body and the

Since the discovery of graphene, advancements within different scientific disciplines have exploded, with huge gains being made particularly in electronics and biotechnology already. The problem that prevented graphene from initially being available for developmental research in commercial uses was that the creation of high quality graphene was a very expensive and complex process, also, it was previously impossible to grow graphene layers on a large scale. This severely limited its use in electronics as it was difficult, at that time, to separate graphene layers from its metallic substrate without damaging the graphene.

However, studies in 2012 found that it is possible to effectually separate graphene from the metallic board on which it is grown, whilst also being able to reuse the board for future applications theoretically an infinite number of times, therefore reducing the toxic waste previously created by this process. Furthermore, the quality of the graphene that was separated by using this method was sufficiently high enough to create molecular electronic devices successfully. While this research is very highly regarded, the quality of the graphene produced will still be the limiting factor in technological applications. Once graphene can be produced on very thin pieces of metal or other arbitrary surfaces then we will start to see graphene become more widely utilized as production techniques become more simplified and cost-effective.

Being able to create super-capacitors out of graphene will possibly be the largest step in electronic engineering in a very long time. While the development of electronic components has been progressing at a very high rate over the last 20 years, power storage solutions such as batteries and capacitors have been the primary limiting factor due to size, power capacity and efficiency (most types of batteries are very inefficient, and capacitors are even less so).

This means that batteries (or capacitors) can be developed to last much longer and at higher capacities than previously realised. Also, it means that electronic devices may be able to be charged within seconds, rather than minute or hours and have hugely improved longevity.

Consumers can already purchase graphene-enhanced products to use at home. One company already produces and offers on the market conductive ink. This is made by effectively mixing tiny graphene flakes with ink, enabling you to print electrodes directly onto paper. While this was previously possible by using organic semi-conductive ink, the use of graphene flakes makes the printed material vastly more conductive and therefore more efficient.

Another use for graphene along similar lines to those mentioned previously is that in paint. Graphene is highly inert and so can act as a corrosion barrier between oxygen and water diffusion. This could mean that future vehicles could be made to be corrosion resistant as graphene can be made to be grown onto any metal surface and due to its strength, graphene is also currently being developed as a potential replacement for Kevlar in protective clothing, and will eventually be seen in vehicle manufacture and possibly even used as a building material.

As graphene has been proven to be much more efficient at conducting electrons than silicon, and is also able to transfer electrons at much faster speeds (30 times faster than silicon), in the next few years you will begin to see products from consumer electronics companies, such as Samsung based on flexible, robust, touchscreen devices such as mobile smartphones and wrist watches.

This could mean foldable televisions and telephones and eventually

electronic flexible newspapers containing all of the publications you

are interested in that can be updated via wireless data transfer. Being

extremely translucent, in the coming years you can also expect to be

able to fit intelligent (and extremely robust) windows to your home,

with (potentially) virtual curtains or displaying projected images of

your choice. Combining a few of these aforementioned potential uses, can

you imagine car security systems that are connected to the paint on your

vehicle? Not only would your car alarm be able to tell you if someone is

touching your vehicle, it would be able to record that information and

send it to

Soon we will begin to see clothing containing graphene-enhanced photovoltaic cells and super-capacitors, meaning that we will be able to charge our mobile telephones and tablet computers in a matter of minutes (potentially even seconds) whilst walking to school or work. We may possibly even see security-orientated clothing offering protection against unwanted contact with the use of electrical discharge.

What all this means is that this discovery, made by a physics professor and his PhD student in a laboratory in Manchester, using a piece of graphite and some Scotch tape has completely revolutionised the way we look at potential limits of our abilities as scientists, engineers and inventors. The possibilities of what we can achieve with the materials and knowledge we have, have been blown wide open, and it is now conceivable to imagine such amazing prospective situations as lightning fast, yet super-small computers, invisibility cloaks, smart phones that last weeks between charges, and computers that we can fold up and carry in our pockets wherever we go.

Have a look at the video below!

The next few years are going to see some wonderful and exciting changes in the way we live and communicate – I can hardly wait!!

Now, if only we can sort out those religious and territorial problems we have……..

Here is an actual sign posted at a golf club in Scotland. Tips:

1. Back straight, knees bent, feet shoulder-width apart. 2. Form a loose grip. 3. Keep your head down! 4. Avoid a quick backswing. 5. Stay out of the water. 6. Try not to hit anyone. 7. If you are taking too long, let others go ahead of you. 8. Don't stand directly in front of others. 9. Quiet, please ... while others are preparing. 10. Don't take extra strokes.

Well done. Now, flush the urinal, wash your hands, go outside and tee off.

The Mighty Airbus A-380

It is incredible how manoeuvrable a huge aircraft like the A380 is when you have no passengers or cargo and not much fuel on board and you toss the keys to two former French Navy pilots and you tell them to “give it heaps”.

These two ex-Military pilots have been working as test pilots for Airbus for some years and one could say they knew their aeroplane pretty well. It is very impressive to see such a big bird gracefully gliding through the skies as though it was a mighty eagle.

See it HERE. Keep one eye on the control surfaces - very interesting.

British Soldier’s Kit.

Over the past 1000 years (or so) the British solder’s kit has changed considerably, as you would expect. But not all – a few items have remained the same over all that time – have a look HERE. (Remember, he/she has to carry all that stuff).

|

|||

|

The doctor says to his elderly patient, 'How long have you been bedridden?' After a look of complete confusion she answered, ' Why, not for about twenty years - when my husband was alive.'

|

|||

|

World War 1.

One hundred years ago, in the summer of 1914, a series of events set off an unprecedented global conflict that ultimately claimed the lives of more than 16 million people, dramatically redrew the maps of Europe, and set the stage for the 20th Century.

HERE are some wonderful photos taken at that time and HERE are some more taken by Australian photographer, Frank Hurley OBE [1885-1962].

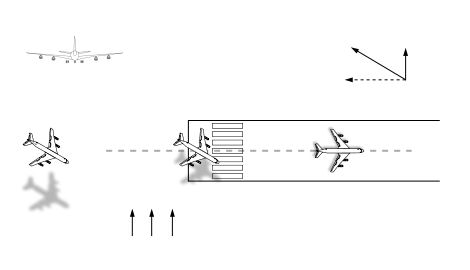

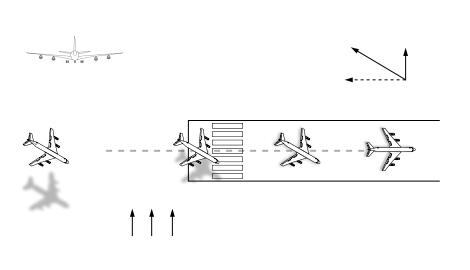

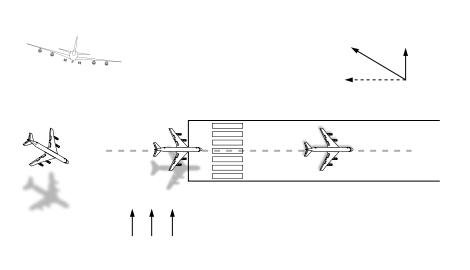

Cross Wind Landing.

Aircraft in flight are subject to the direction of the winds in which the aircraft is operating. For example, an aircraft in flight that is pointed directly north along its longitudinal axis will, generally, fly in that northerly direction. However, if there is a wind from the west, the actual track of the aircraft will be slightly to the east of north. If the aircraft was landing north on a north-south runway, it would need to compensate for this easterly drift caused by the west crosswind.

In situations where a crosswind is present, the aircraft will drift left or right as it approaches the runway. This drift poses significant safety issues because safe operation of the undercarriage requires the body and track of the aircraft to be aligned with the runway at touch down. The landing gear designs of the "pioneer era" 1909 Bleriot XI, and the much later Cold War B-52 strategic jet heavy bomber, were designed and each built with an unusual feature to counteract the problem: with the B-52, all four of its landing gear bogies could be steered, allowing the aircraft to land with the wheels facing the direction of travel even if the nose was not pointed in the same direction. The Bleriot XI had pivoting main gear legs, which passively allowed the main gear wheels to castor together about each of their vertical axes as a unit to allow small-angle crosswind landings, with bungee-cord loaded rigging members between the lower ends of the main wheel forks, to bring the wheels back to a "directly-ahead" orientation after touchdown.

If the crosswind landing is not executed safely, the aircraft may experience wingstrike, where a wing hits the runway.

The following guidelines are advised by Boeing for a crosswind landing. These guidelines assume steady wind (no gusting). These winds are measured at 10 m (33 feet) tower height for a runway 45 m (148 feet) in width. Basically, there are 3 landing techniques which may be used to correct for cross winds: de-crab, crab, and sideslip.

De-crab. The objective of this technique is to maintain wings level and the aircraft positioned near the runway centreline during approach. The nose points into the wind so that the aircraft approaches the runway slightly skewed with respect to the runway centreline (crabbing). This gives the impression of approaching the runway flying sideways, which can be disorienting for the pilot. Position is maintained by balancing the crosswind component, or more accurately the drag force arising from it, with engine thrust. Wings are maintained level throughout the approach. Just before the flare, opposite rudder (downwind rudder) is applied to eliminate the crab, with a simultaneous application of opposite aileron to maintain a wings-level attitude, so that at touch down, the body, velocity vector, and bank angle are all aligned with the runway, and the aircraft is positioned near the centre.

Crab The airplane can land using crab only (zero side slip) up to the landing crosswind guideline. On dry runways, upon touchdown the airplane tracks towards the upwind edge of the runway while de-crabbing to align with the runway. Immediate upwind aileron is needed to ensure the wings remain level while rudder is needed to track centre line. The greater the amount of crab at touchdown, the larger the lateral deviation from the point of touchdown. For this reason, touchdown in a crab only condition is not recommended when landing on a dry runway. On very slippery runways, landing the airplane using crab only reduces drift towards the downwind side of a touchdown, and may reduce pilot workload since the airplane does not have to be de-crabbed before touchdown. However, proper rudder and upwind aileron must be applied after touchdown to ensure directional control is maintained.

Sideslip. This sideslip crosswind technique is to maintain the aircraft's heading aligned with the runway centreline. The initial phase of the approach is flown using the Crab technique to correct for drift. The aircraft heading is adjusted using opposite rudder and ailerons into the wind to align with the runway. This places the aircraft at a constant sideslip angle, which its natural stability will tend to correct. Sufficient rudder and aileron must be applied continuously to maintain the sideslip at this value. The dihedral action of the wings has a tendency to cause the aircraft to roll, so aileron must be applied to check the bank angle.

With a slight residual bank angle, a touchdown is typically accomplished with the upwind main wheels touching down just before the downwind wheels. Excessive control must be avoided because over-banking could cause the engine nacelle or outboard wing flap to contact the runway/ground. In strong crosswind conditions, it is sometimes necessary to combine the crab technique with the sideslip technique. This technique is also called a forward slip and is used whenever the aircraft is too high on approach, and there needs to be a rapid reduction of altitude without a gain of airspeed in order to conduct a safe landing.

There are some wonderful examples of cross-wind landings HERE though I must admit I am glad I wasn’t on any of them.

|

|||

|

|

|||

|

|

|||

|

New initiative linking injured veterans to employment.

Recognising the unique nature of military service, Senator the Hon Michael Ronaldson said today, “I am pleased to announce a new trial initiative that will help wounded, injured or ill veterans achieve employment opportunities as part of their recovery.

As a nation, we owe a great debt to the men and women who have served in our Defence Force. It is incumbent upon us to do everything we can to facilitate the rehabilitation of those who have been injured and to help them transition to post service employment.

This trial Veterans Employment Assistance Initiative builds on the traditional approach to rehabilitation and brings a greater focus in linking veterans to employment opportunities.

Under the trial Initiative, veterans who have identified that they wish to return to work will undergo early assessment of their vocational rehabilitation needs. This will include aligning the skills they have developed in the Australian Defence Force (ADF) to potential civilian employment opportunities. Participants will also undertake employment focused training in line with their abilities and aspirations.

Those who have served in the ADF bring to future employment a unique range of skills and experiences. I am sure that every Australian will join with me in wanting those veterans who need assistance, and their families, to improve their wellbeing, restore their independence, realise their skills and capabilities, and secure meaningful employment.

Today I presented Downer EDI Works with a certificate of appreciation, in recognition of their employment of a former ADF member.

I have asked my Department to work closely with employers to match employment opportunities with veterans and ensure the best outcome for all. The Veterans Employment Assistance Initiative will broaden the vocational and non-vocational assistance and support available to former ADF members.

This initiative will further strengthen our already world-leading repatriation system by assisting those who wish to return to employment following injury.

The Veterans Employment Assistance Initiative is being undertaken as a

trial in Queensland involving up to 50 participants and will help inform

a future national approach".

|

|||

|

|

|||

|

"Impossible" Electric Airplane Takes Flight

The recent Berlin Air Show witnessed a silent, clean test flight by Airbus's E-Fan two-seater aircraft, which is entirely propelled by electricity. When a Panavia Tornado blasted into the clouds above the Berlin Air Show before swooping back down toward the Earth, the grounds below shook from the roar of the fighter bomber's twin engines.

When the next aircraft took to the sky, the air show went eerily quiet.

The fully electric E-Fan aircraft, engineered by the Airbus Group, made one of its first public demonstrations following it's first-ever flight in France in March. The novel two-seater aircraft was designed from the outset for electrical propulsion, from its energy management system to safety features

"It's a very different way of flying," said Jean Botti, chief technical and innovation officer at Airbus Group, "absolutely no noise, no emissions." A series of lithium-ion batteries fitted into the wings of the plane are the sole power source for the E-Fan's two 30-kilowatt electric motors. A 6 kW electric motor in the main wheel provides extra power during acceleration and taxiing to reduce electrical power consumption on the ground.

But despite its highly energy efficient design, the E-Fan only has a one-hour range, which means it cannot leave the vicinity of an airport. To combat range anxiety, the plane is outfitted with a backup battery for landing purposes and a parachute that can be deployed as high as 2,000 feet.

Like an electric car, a gauge on the dashboard tells the pilot how much energy is in the batteries and the plane is plugged in when it needs to recharge. "We're trying this. It's not to enter the business of small aircraft," Botti said. "It's to learn to make a new business."

Airbus Group's ultimate goal is to make a 70 to 80 person hybrid-electric commuter jet with three hours of range in the 2050 time frame. Initial designs of the E-Thrust aircraft show the plane with six electric-powered fans that will be powered by a gas-fueled energy storage unit during the ascent and cruise phase and then glide using electric power alone while descending. In the next step toward achieving this, Airbus will make a next-generation two-seater electric plane, set for launch in 2017, and a four-seater electric plane with a gas-powered range extender, set for launch in 2019.

US War graves, Maastricht.

About six miles from Maastricht in the Netherlands lie buried 8,301

American soldiers who died in "Operation

Market Garden" in the battle to liberate Holland in September 1944.

The day concludes with a concert. The final piece is always "IL Silenzio", a memorial piece commissioned by the Dutch and first played in 1965 on the 20th anniversary of Holland's liberation. It has been the concluding piece of the memorial concert ever since.

Recently the soloist was a 13 year old Dutch girl, Melissa Venema, backed by André Rieu and his orchestra (the Royal Orchestra of the Netherlands). This beautiful concert piece is based upon the original version of taps and was composed by Italian composer Nino Rossi.

You can watch it HERE – volume up and go full screen.

|

|||

|

At the beginning of his shift the doctor placed a stethoscope on an elderly and slightly deaf female patient's anterior chest wall. 'Big breaths,' he instructed. 'Yes, they used to be,' she said!

|

|||

|

The Boneyard.

You have to wonder why the US of A would want to keep all those old aircraft out in the desert as they do, it’s not as if they are going to fly them again, most are so old they could vote and the money (you would think) wasted in hibernating them could be spent elsewhere, surely?? You wonder why they haven’t been melted down and turned into pots and pans – has to be a very good reason you would think…..

Have a look HERE.

|

|||

|

|

|||

|

|

|||

|

Velly Intelesting – but stupid!!!!

|

|||

|

|

|||

|

|

|||

|

Back Go to page: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Forward |

|||

|

|

-efficient. In the meantime, aerogels can

be found in a range of products:

-efficient. In the meantime, aerogels can

be found in a range of products: fourth most abundant element in the universe (by mass), after hydrogen,

helium and oxygen. This makes carbon the chemical basis for all known

life on earth, so therefore graphene could well be an ecologically

friendly, sustainable solution for an almost limitless number of

applications.

fourth most abundant element in the universe (by mass), after hydrogen,

helium and oxygen. This makes carbon the chemical basis for all known

life on earth, so therefore graphene could well be an ecologically

friendly, sustainable solution for an almost limitless number of

applications.  Graphene

is now being used to boost not only the capacity and charge rate of

batteries but also the longevity. Currently, while such materials as

silicone are able to store large amounts of energy, that potential

amount diminishes drastically on every charge or recharge. With graphene

tin oxide being used as an anode in lithium ion batteries for example,

batteries can be made to last much longer between charges (potential

capacity has increased by a factor of 10), and with almost no reduction

in storage capacity between charges, effectively making technology such

as electronically powered vehicles a much more viable transport solution

in the future.

Graphene

is now being used to boost not only the capacity and charge rate of

batteries but also the longevity. Currently, while such materials as

silicone are able to store large amounts of energy, that potential

amount diminishes drastically on every charge or recharge. With graphene

tin oxide being used as an anode in lithium ion batteries for example,

batteries can be made to last much longer between charges (potential

capacity has increased by a factor of 10), and with almost no reduction

in storage capacity between charges, effectively making technology such

as electronically powered vehicles a much more viable transport solution

in the future.  you via your smartphone in real-time. It could also be used to analyse

vehicle accidents to determine initial contact patches and resultant

consequential energy dispersion.

you via your smartphone in real-time. It could also be used to analyse

vehicle accidents to determine initial contact patches and resultant

consequential energy dispersion.

Everyone of the men buried in the cemetery, as well as those in the

Canadian and British military cemeteries, has been adopted by a Dutch

family who mind the graves, decorate, and keep alive the memory of the

soldier they have adopted. It is even the custom to keep a portrait of

"their" American soldier in a place of honour in their home. Annually on

"Liberation Day" Memorial Services are held for "the men who died to

liberate Holland."

Everyone of the men buried in the cemetery, as well as those in the

Canadian and British military cemeteries, has been adopted by a Dutch

family who mind the graves, decorate, and keep alive the memory of the

soldier they have adopted. It is even the custom to keep a portrait of

"their" American soldier in a place of honour in their home. Annually on

"Liberation Day" Memorial Services are held for "the men who died to

liberate Holland."