|

|

||

|

||

|

Privacy Policy | Editorial Policy | Profit Policy | Join the Association | List of Members | Contact us | Index | Links |

||

|

Back Go to page: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Forward

|

||

|

Allan George’s Gems.

|

||

|

|

||

|

Insurances.

When you insure your car or your house and contents or even your life, do you know who the underwriter is? It’s a bit of an eye-opener really….. IAG own both CGU and NRMA and are the largest insurer of Australians.

SUNCORP own SUNCORP, GIO, VERO, AAMI, Shannon’s, APIA, RACQ, RACV, RACT and is the 2nd largest insurer of Australians.

QBE may well be the largest Australian insurer but over 69% of their business is overseas business.

YOUi is owned by a South African insurer called Outsurance.

Budget Direct is owned by a South African Insurer called Auto & General.

Real is owned by a South African Insurer called Hollard.

Defence Service Homes Insurance is underwritten by QBE.

Progressive is owned by an American insurer believed to be the largest motor insurer in Chicago.

It’s called brand separation and is to ensure they get your money whichever way you turn.

And what about “iselect” which claims to provide choice but which actually suggests 9 brands which are underwritten by the one insurer, the South African Auto & General. As a comparing insurer, iselect put up Dawes which is owned by Calliden and which specializes in the prestige end of the market and wouldn't even write the business that Auto & General write, so there is no true comparison at all, only comparison of brands.

So, while you hear the public MOAN about Woolworths and Coles holding such a large market share, what about the Insurance Companies??..

I don't believe in astrology. I am a Sagittarius and we're very sceptical.

The pro's and con's of nitrogen for tyres.

The subject of using nitrogen to inflate car tyres has received considerable publicity over the past few years; particularly since some tyre retailers have begun promoting its supposed benefits. It is well known that nitrogen gas has been used to inflate the tyres of racing cars, aircraft and heavy commercial vehicles for some time, however it is only relatively recently that it has come into use in normal passenger cars.

|

||

|

|

||

|

So, what is nitrogen?

Nitrogen is a colourless, odourless, tasteless, and non-toxic gas that forms about 78% of the Earth's atmosphere. The benefits claimed for using nitrogen over compressed air for inflating tyres are that it:

· Reduces the tyre's running temperature. · Improves the ride quality. · Increases tyre life. · Keeps tyre pressures more constant. · Slows the rate of pressure loss. · Doesn't react with the tyre and rim materials.

Reduces the tyre's running temperature. While there is some truth in this statement, the difference relates to the moisture content of the inflation gas rather than the use of nitrogen per se. In fact, dry compressed air will also produce a cooler running tyre. It's also only likely to be of benefit in cases where the tyres are operating at or near their maximum load and/or speed capacities.

Nitrogen improves ride quality. No explanation has been offered as to why this should be the case. There should be no significant difference in the way air and nitrogen behave at normal tyre operating pressures and temperatures.

Nitrogen increases tyre life. A tyre's operating temperature plays a part in how rapidly it will wear. A reduction in temperature at high speeds and loads will be beneficial, however claims by some supporters that nitrogen will double tyre life are questionable.

Reduced pressure build up. The reason that tyre pressures should only be checked when cold is that the tyre’s inflation pressure increases in relation to temperature. Nitrogen is claimed to provide a more stable pressure range in relation to tyre temperature. However once again the moisture content of the inflation gas plays a bigger part than the gas itself. Any benefits are likely to be achieved only under heavy load and/or high-speed conditions.

Pressure loss is slower with nitrogen than with air. Tyre liners and tubes are to some degree porous, and as a result air will eventually leach out. Hence the need to regularly check tyre pressures. Nitrogen, due to its chemical structure, is slower to leak out than compressed air, therefore the pressure loss is slower. However that doesn't mean that regular pressure checks can be neglected as there is still the possibility of a puncture or some other form of slow leak.

Nitrogen doesn't react with the metal wheel rim or the tyre materials. Probably true. The presence of oxygen and moisture inside the tyre can cause oxidisation (rust) of the metal components. There is also a suggestion that air reacts with the rubber of the tyre itself, however it is not clear if this is detrimental or in any way reduces the life of the average car tyre. Because nitrogen is a relatively inert gas (though not a member of the 'noble' gas family) and because it is dry, this problem is, in theory, eliminated. However, unless the tyre is evacuated (i.e. all the air is removed) before the nitrogen is added, there will still be some air and possibly moisture in the tyre.

Disadvantages of nitrogen, Nitrogen also has a few disadvantages that should be taken into account. These include:

·

Cost · Maintenance · Availability

Cost. The typical charge for nitrogen is between $5 and $10 per tyre for a passenger car.

Maintenance. Once your tyres are filled with nitrogen it's important that only nitrogen is used for top up purposes. Adding normal compressed air will negate any benefits of the nitrogen. If you are in an area where nitrogen is not available and top up is necessary, normal compressed air will have to be added. If you wish to reinflate with nitrogen later you will need to locate a nitrogen outlet, deflate the tyre and then reinflate it with nitrogen.

Availability. Nitrogen simply isn't readily available everywhere. It's generally restricted to specialist tyre dealers.

A few things to consider. The earth's atmosphere is comprised of roughly 78% nitrogen and 21% oxygen with a few trace gasses mixed in, so when you fill your tyres with compressed air, you are getting about 78% nitrogen anyway.

Not all aircraft use nitrogen in their tyres. In fact, generally only larger aircraft with high altitude capability and high landing and take-off speeds and high loads use it. The reason given by the Civil Aviation Safety Authority to support its use is that nitrogen, being a relatively inert gas, reduces the risk of high altitude tyre explosions that could damage or destroy an aircraft. Obviously, this is hardly a consideration for the average passenger car operator.

Nitrogen is also sometimes used in the tyres of vehicles that operate in potentially hazardous areas, such as mines, to reduce the risk of fire. It is also commonly used in off-highway vehicles where the tyres operate at their maximum load and are highly stressed.

A number of tyre manufacturers have produced position papers on nitrogen, as has the Australian Tyre Manufacturers Association. Some tyre manufacturers have declined to comment. Most have indicated that tyre warranties will not be affected by the use of nitrogen.

Summary. While using nitrogen in passenger car tyres may produce some benefits in some applications, it is questionable if the average motorist will derive any measurable benefit from its use. Using nitrogen does not remove or reduce the need to check tyre pressures as the risk of a puncture or a slow leak is not altered.

Many of the benefits claimed of nitrogen could be achieved by using dry compressed air from a properly designed and maintained compressed air system. Nitrogen cannot replace regular maintenance. Regardless of what inflation gas is used, maximum tyre life will only be achieved if the vehicle and tyres are properly maintained. That means regular checking of tyre pressures, wheel balance and alignment.

You can see an informative video on the use of nitrogen below.

|

||

|

|

||

|

|

||

|

Off to Mars.

Josh Richards is one of the remaining 'Mars 100' from an initial field of 200,000 applicants. The Dutch-based Mars One Project is a private consortium that plans to populate Mars with humans. By the end of 2016, the 'Mars 100' will be whittled down to an astronaut corp of 24 people who will spend the next decade preparing to go to Mars.

Ultimately, four of those astronauts will travel to, and live on Mars, with no possibility of returning to earth.

Josh has a background in applied physics and psychology, and has worked as a combat engineer with the Australian and British Armed Forces.

Recently he was interviewed on the ABC show "Conversations" by Richard Fidler. It's very interesting, you can hear it HERE |

||

|

|

||

|

Paddy and Mick were driving down the road drinking a couple of beers. The passenger, Mick, suddenly said, 'Lord tundering.... up ahead -- it's a police roadblock!! We're gonna get busted for drinkin' dese here beers!!' 'Don't worry,' Paddy said. 'We'll just pull over and finish dese beers, then peel off the label, stick it on our foreheads and throw the bottles under the seat.' 'What fer?' 'Jist let me do de talkin', OK?' So they finished their beers, threw the empties out of sight and put a label on each of their foreheads. When they reached the roadblock, the Royal Irish Constabulary officer took a long look at the two of them and said, 'You boys been drinkin'?'

'No at all,' said Paddy, pointing at the labels. 'We're on the patches.’

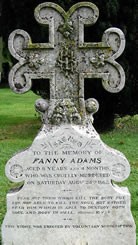

Sweet F.A. (Fanny Adams).

Everybody at one time or another has either said or heard the phrase, “Sweet F.A.”. The F.A. is the polite way of saying something a bit crude and over time it has evolved into Sweet Fanny Adams – which of course means the same thing.

But who is/was Fanny Adams.

The eight-year-old Fanny Adams was murdered in Alton, England in August 1867 by Frederick Baker, a 24-year-old solicitor's clerk. Her dismembered body was found in a field near the town. She was buried in Alton cemetery and the inscription on the headstone clearly indicates the strength of feeling against the murderer:

Sacred to the memory of Fanny Adams aged 8 years and 4 months who was cruelly murdered August 24th, 1867.

Fear not them which kill the body, but are not able to kill the soul but rather fear Him who is able to kill both body and soul in hell.

Matthew 10:28.

This stone was erected by voluntary subscription."

The case was the source of enormous public concern and newspaper reports of the time concentrated on the youth and innocence of the victim. Everyone living in England at the time would have known the name of 'sweet' Fanny Adams. With typical grisly humour, sailors in the British Royal Navy came to use the expression to refer to unpleasant meat rations they were often served - likening them to the dead girl's remains. Barrère and Leland recorded this usage in their dictionary of slang, jargon and cant, 1889:

"Fanny Adams (naval), tinned mutton."

It wasn't until later that 'sweet Fanny Adams' came to mean 'nothing'. The term 'f@#* all' has long been with us with that meaning, although how long isn't clear as politeness caused it not to be recorded in print until the 20th century. It surely dates back to at least the early 19th century. The coincidence of Fanny Adams' initials caused F.A. or 'Fanny Adams' to be used as a euphemism for ' f@#* all'.

Walter Downing, an Australian soldier who fought in Europe in the First World War, wrote a glossary of WWI soldier's slang called Digger Dialects in 1919. He is the first to record the link between F.A. (meaning ' f@#* all') and Fanny Adams:

|

||

|

Any intelligent fool can make things bigger and more complex. It takes a touch of genius - and a lot of courage, to move in the opposite direction.

|

||

|

Regular unleaded petrol facing crackdown.

AUSTRALIA’S most popular petrol would be phased out within two years under a plan to improve fuel quality standards being proposed by the Turnbull government.

In a discussion paper released this week (22 December 2016), the government proposes five scenarios to update existing fuel standards, one of which would see 91 octane regular unleaded petrol “phased out” over two to five years.

Australian fuel is rated the “dirtiest” out of 35 OECD countries based

on sulphur content. The go

In NSW, premium makes up 54 per cent of petrol sales, followed by E10 with 36 per cent and 10 per cent for regular. Nationally excluding NSW, premium accounts for 23 per cent and E10 just 4 per cent.

On average, 95 octane premium unleaded is 11.5 cents per litre more expensive than regular petrol, and 98 octane is 18.5 cents per litre more expensive. The paper says “particular attention” will be given to the impacts of the proposals “across socio-economic groups”, which it says is “particularly relevant for the phase out of [regular] unleaded petrol”.

NRMA spokesman Peter Khoury said while there was “no doubt we need to make our fuel cleaner”, there would be a large “cost factor” for consumers in getting rid of regular unleaded petrol. “The gap between E10 and 98 octane on average is 21 cents per litre, and on any given day it can be as much as 30 cents or 40 cents,” he said. “There are no safeguards in place to protect motorists from exorbitant charges when these fuels come in, and if you’re taking out 91 octane you’re giving them no choice.” NRMA doesn’t agree with government’s position that the higher costs of new cars under the new environmental standards would be offset by savings from greater fuel efficiency.

Manufacturers lab test their cars, real world performance is much worse. Actual performance is 20 per cent worse, in some instances 35 per cent worse than what the manufacturers are telling us. The government needs to tell people what the costs are going to be based on the actual costs, not costs based on false data and the best way to do that is for the government to take a leadership role in performing real-world testing.

Five proposals to reform fuel standards.

1. Australia’s fuel standards remain in effect in their current form (business as usual). Petrol standards retained: unleaded petrol (91 RON) with a maximum sulphur limit of 150 ppm; premium unleaded petrol (95 RON) with a maximum sulphur limit of 50 ppm. Diesel standard continues to specify a maximum sulphur limit of 10 ppm and derived cetane number of 51 for diesel containing biodiesel only. 2. Revisions to the fuel standards to align with the recommendations of the Hart Report and to harmonise with European standards. Unleaded petrol (91 RON) would be phased out over a specified period of time (e.g. two to five years). Sulphur in premium unleaded petrol (95 RON) would be limited to 10 ppm and a new octane standard for premium unleaded petrol (98 RON) introduced. More stringent requirements would be introduced for cetane and polycyclic aromatic hydrocarbon levels in diesel.

3.

Revisions to the fuel standards to align with the recommendations of the

Hart Report and to harmonise with 4. Revisions to the fuel standards as per alternative B above, except with even stricter parameters (including for cetane levels in diesel) to harmonise with the standards recommended by the Worldwide Fuel Charter (that recommends the fuel quality required by car companies to meet particular emission standards). 5. Staged introduction of world standards from 2020, with a review in 2022 to determine next steps. Unleaded petrol (91 RON) would be retained. Sulphur would be reduced to 50 ppm for unleaded petrol (91 RON) and 25 ppm for premium unleaded petrol (95 RON) and a new octane standard for premium unleaded petrol (98 RON) introduced. Revisions to other parameters as per alternative 2 above.

|

||

|

Imagination is more important than knowledge.

|

||

|

Fuel Octanes.

An octane rating, or octane number, is a standard measure of the performance of an engine or aviation fuel. The higher the octane number, the more compression the fuel can withstand before detonating (igniting). In broad terms, fuels with a higher octane rating are used in high performance gasoline engines that require higher compression ratios. In contrast, fuels with lower octane numbers (but higher cetane numbers) are ideal for diesel engines, because diesel engines (also referred to as compression-ignition engines) do not compress the fuel, but rather compress only air and then inject fuel into the air which was heated by compression. Gasoline engines rely on ignition of air and fuel compressed together as a mixture, which is ignited at the end of the compression stroke using spark plugs. Therefore, high compressibility of the fuel matters mainly for gasoline engines. Use of gasoline with lower octane numbers may lead to the problem of engine knocking.

In a normal spark-ignition engine, the air-fuel mixture is heated due to

being compressed (get a bike pump, put you

The average compression ratio of a petrol engine is usually somewhere between 8 and 12 to 1. The compression ratio is obtained by calculating the total volume of the cylinder when the piston is at its lowest point and comparing it to the volume left in the cylinder when the piston is at top dead centre (TDC).

(Diesels usually operate at a compression ratio between 15 and 22 to 1)

The most typically used engine management systems found in automobiles today have a knock sensor that monitors if knock is being produced by the fuel being used. In modern computer-controlled engines, the ignition timing will be automatically altered by the engine management system to reduce the knock to an acceptable level.

You can see a good video on fuels and fuel octanes below.

|

||

|

|

||

|

|

||

|

|

||

|

How a vehicle’s differential works.

Everyone knows that cars and trucks have differentials (diffs), on some cars you can see them as they are that bulge in the middle of the back axle but in a lot of cases you can’t see them as they are mixed up in the engine thingy in front drive cars. We all know they are necessary and cars and/or trucks wouldn’t corner all that well if they didn’t have one. But who invented them and how do they work.

|

||

|

There are many claims to the invention of the differential gear and it is possible that it was known, at least in some places, in ancient times. As far as the modern vehicle diff goes, the majority of people accept it was invented in 1827 by a Frenchman, watch-maker Onésiphore Pecqueur. It was used first on steam-driven vehicles and was a well-known device when internal-combustion engines appeared at the end of the 19th century.

In 1913 the US car maker Packard introduced the spiral-gear diff which cut down gear noise considerably then in 1926 it invented the hypoid diff with the drive shaft entering the bottom of the diff housing enabling the drive shaft and its hump in the interior of the car to be lowered.

But how do they work.

If you do a Google search, you can find lots of descriptions on how the diff works but in a lot of cases the language is aimed at engineers, it is hard to understand. Luckily, there is a video which explains it in language that even a Radtech could understand it. (PS: There is a replay button for Telstechs).

See the video below. |

||

|

|

||

|

|

||

|

We are here on earth to do good unto others. What the others are here for, I have no idea.

|

||

|

Cricket.

The Australian cricket season has nearly come to an end for another year, we won a few and we lost a few and all in all, it was a successful season. Where once a score of 250 in a 50 over game was quite enough to ensure success, these days you need 350 to be assured of a win. Why is that, are the players getting better, are the bowlers getting worse, is it the ball or is it the bat? Most agree the cricket bat is a much better weapon that it used to be and the ICC has conceded that modern bats have shifted the balance towards batsman.

While a cricket bat must not be greater than 4.25 inches (10.8cm) in width and not greater than 38 inches (96.5cm) in length there is no limit on its depth. Bats have become thicker and the “sweet spot” on the face of the bat is now about 2½ times what it used to be. The ICC have looked at this and have not yet decided to place any restrictions on bat width, possibly because fans love to see runs, the popularity of the 20:20 game proves this. There is some discussion amongst members of the ICC to limit bat thickness but to date not all members are keen to impose a restriction.

Professional cricket bats are made from white willow (salix alba) which is native to Europe and western and central Asia. This wood, while being light in weight, is tough and shock resistant, meaning it can handle the high-speed impact of a cricket ball without splintering on impact. It is done like this:

Click HERE to see how bats have evolved over the years.

There is a good video on how they made a bat back in 1962 – you can see it below. |

||

|

|

||

|

|

||

|

During a commercial airline flight an experienced RAAF Pilot was seated next to a young mother with a babe in arms. When the baby began crying during the descent for landing, the mother began nursing the infant as discreetly as possible. The pilot pretended not to notice, and, upon disembarking, he gallantly offered his assistance to help with the various baby-related items. When the young mother expressed her gratitude, the pilot responded, "that's a good looking baby, and he sure was hungry!"

Somewhat embarrassed, the mother explained that her paediatrician said that the time spent on the breast would help alleviate the pressure in the baby's ears. The RAAF Pilot sadly shook his head, and in true pilot fashion exclaimed, "And all these years, I've been chewing gum."

|

||

|

|

||

|

The RAAF's aeroplanes. We've been sent a video of the RAAF's aircraft doing what they were trained to do. It's a bit old as it features the Mirage and the proper Hercs that we once had (the A Model). You can see it below, worth a look! |

||

|

|

||

|

Funny?

THIS is a bit silly - but I bet you get a laugh from watching it. It will take few seconds to open, please be patient.

|

||

|

|

||

|

|

||

|

|

||

|

Velly Intelesting – but stupid!!!!

|

||

|

|

||

|

|

||

|

Back Go to page: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Forward |

||

|

|

vernment’s

proposals centre around setting maximum sulphur limits, which would

potentially cost the country’s remaining four oil refineries billions of

dollars to implement. Regular unleaded petrol makes up 73 per cent of

all petrol sold in Australia excluding NSW, where the state government’s

ethanol mandate has driven motorists to buy more expensive premium

unleaded, shunning E10.

vernment’s

proposals centre around setting maximum sulphur limits, which would

potentially cost the country’s remaining four oil refineries billions of

dollars to implement. Regular unleaded petrol makes up 73 per cent of

all petrol sold in Australia excluding NSW, where the state government’s

ethanol mandate has driven motorists to buy more expensive premium

unleaded, shunning E10.

European standards as per alternative B above, except that unleaded

petrol (91 RON) is retained but with a lower sulphur level of 10 ppm.

European standards as per alternative B above, except that unleaded

petrol (91 RON) is retained but with a lower sulphur level of 10 ppm. r

finger over the outlet hole and pump the handle – it gets hot due to

compression) and is then triggered to burn rapidly by the spark plug. If

it is heated (or compressed) too much, it will self-ignite before the

ignition system sparks. This causes much higher pressures than engine

components are designed for, and can cause a "knocking" or "pinging"

sound. Knocking can cause major engine damage if severe.

r

finger over the outlet hole and pump the handle – it gets hot due to

compression) and is then triggered to burn rapidly by the spark plug. If

it is heated (or compressed) too much, it will self-ignite before the

ignition system sparks. This causes much higher pressures than engine

components are designed for, and can cause a "knocking" or "pinging"

sound. Knocking can cause major engine damage if severe.