B52 Re-enginered?

It seems that the USAF cannot get through a year without being inundated with calls to replace the engines on the B-52. Recent calls from Air Force Global Strike Command, Boeing, General Electric and Pratt & Whitney have renewed the vigour of the program despite the general lack of funding and enthusiasm for large dollar aircraft procurement. Fuel savings and increases in capability are touted as the driving factors in these programs. However, for the B-52 these arguments show little merit when they are studied with any depth.

Where it concerns the B-52, we are fortunate that there is a long and well documented history of the design process. Not only do we know the specifics of the design, we know why it was designed a specific way. Its strengths and weaknesses have been well vetted through a half century of combat. That history can guide us towards a full understanding of what a re-engine program may entail.

Re-Engine Programs.

Upgrades to existing systems are done for a variety of reasons. Typical upgrades are used to correct a deficiency or to create a required capability. There have been cases where upgrades are done to ensure a particular system remains viable in a new environment. Sometimes upgrades solve logistical problems as certain parts are no longer produced and an upgraded system is necessary to continue using the whole aircraft. For example, in the early 2000s the B‑52 upgraded its 1970s‑era beryllium ball inertial navigation system with a modern ring-laser gyro system in order to correct a failed supply line, not to increase its navigation performance.

Generally speaking, airframe efficiency evolves much slower than engines. These upgraded engines always appeal to operators with the same line: better utility and lower costs. Newer engines provide better range, longer loiter time, less fuel, more thrust, reduced maintenance, and many other benefits. Therefore, with all of these advantages, re-engine programs should be much more prevalent.

Commercial re-engining programs, as we know them, began in the 1970s when the Environmental Protection Agency enacted emissions and noise restrictions on turbojet engines. The commercial market reacted with new aircraft that were equipped with more efficient engines with a smaller noise footprint, rather than attempt wideband re-engine programs. However, the two most popular aircraft, the Douglas DC-8 and Boeing 707 did attempt re-engine programs. The DC-8 upgraded their Dash 60s with JT3D engines to the Super 70 series equipped with a more efficient CFM56 high-bypass turbofan. The engines were more efficient with a smaller noise footprint, but the DC‑8 actually lost takeoff performance in the conversion. The engines were much heavier, therefore the DC‑8 lost some payload capacity. The 707 attempted something similar, also with the CFM56, but found that smaller orders limited their profits. They also felt an upgraded 707 was competition to the new 757 and scrapped the program to all but a few customers. In the large aircraft, large fleet categories, these represent the bulk of re-engine programs for the past 30 years. It was simpler and cheaper to just make a new airplane.

On the military side, re-engine programs were fairly scarce. Businesses wish to operate at a profit, therefore cost savings is all-important. These programs were designed to save fuel. Governments, specifically militaries, do not necessarily need to operate in such a manner. However, in the USAF has made these decisions in the past. The C/KC‑135 was re-engined twice. In the 1980’s the USAF re-engined all of the Reserve and Guard KC‑135s with the TF‑33 turbofan. Not only did the KC-135 get more thrust (7,000 pounds of thrust increase per engine), they also saw a 14% increase in fuel efficiency and was capable of off-loading 20% more fuel to receivers. The active duty KC-135s were also upgraded later, these to the CFM56 high bypass turbofan. This provided a 100% increase in thrust over the original KC‑135. The newest KC-135 is 25% more fuel-efficient, with 60% increase in range, can offload 50% more fuel, and costs 25% less to operate than its original version. This data suggests re-engine programs are a slam dunk, no-brainer in the world of aircraft acquisitions. It begs the question, why are these programs not taking place everywhere? Because fuel savings alone is not enough to justify the cost of new engines.

Fuel Savings.

In order to understand why these types of programs generally do not pass the cost-benefit curve in the area of fuel savings, it is important to understand how the USAF consumes and pays for fuel.

In all air fleets, there are two types of cost, (1) Fixed Annual Cost, and (2) Variable Costs. Fixed costs are those that must be paid regardless of usage. If the aircraft flies 1 hour or 1,000 hours the fixed cost is the same. The variable cost is dependent on how much the aircraft flies. More flying, more cost. The USAF sinks 90%-95% of its overall cost in the fixed category, meaning USAF aircraft cost the same no matter how much they are flown. This is backwards from how commercial aircraft are operated. The USAF does this because it does not utilize its aircraft nearly as much as a commercial carrier. The average USAF non-fighter, large aircraft flies approximately 350 hours per aircraft per year. By comparison, the average US commercial airliner files approximately 3,000 hours per aircraft per year. In the commercial world, idle aircraft are lost revenue. Commercial airlines have far more variable cost, therefore fuel prices and fuel consumption have a significantly greater effect on a commercial fleet’s profitability. Fuel consumption and efficiency is almost negligible for the USAF.

When the B-52 re-engined to the TF33 between the G and H-models, it realized a 20% fuel savings similar to the savings realized for the KC‑135. Studies have shown that a similar fuel savings (up to 25%) could be realized with modern engines. But that kind of savings just does not make a dent in the USAF budget nor does it cover the cost of the engines, the program, or the management. The B-52 burns, on average, 88 million gallons of jet fuel per year representing 5% of the total jet fuel in the USAF. Even if the USAF could reduce fuel consumption in its entire fleet of aircraft, all of them, by 25% and save more than 500 million gallons of fuel per year it would save $1B per year. Sounds like solid savings, however that represents less than 1 percent of the USAF budget.

In the past 20 years there have been no less than eight separate official studies on the subject of replacing the engines on the B-52. Sometimes the study looked only at the B-52, sometimes it encompassed the entire USAF fleet, sometimes only those who utilize a particular engine. In all cases they found fuel savings and fuel efficiency are not reason enough to justify the cost of the program.

Hidden Costs of Re-Engine Programs.

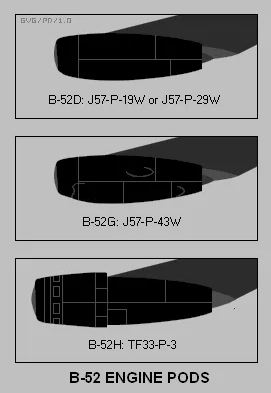

When aircraft are designed, they are designed with a particular engine in mind. Sometimes one is developed before the other, but the integration of the two is a marriage of design of the highest importance. When the engine is changed, no matter how much analysis and planning is done, the program will experience unforeseen operational implications. It is inevitable; you have changed an integral part of the holistic design of the aircraft. Engine retrofits are backwards in the aircraft-engine marriage. Initial designs optimize performance, while re-engine programs strive to minimize complications. The B-52 was designed to handle the Pratt-Whitney J57 turbojet engine. Over the years, several variations have been flown, but all of them have been the J57 or derivatives thereof. The TF33 is the turbofan derivative of the J57.

One outset of the KC-135 re-engine program, it was viewed as a straight forward engine replacement. However, the USAF was unable to complete the program without unnecessary cost and schedule overruns. Even with all of the data and lessons learned from the DC‑8 and 707 re-engine program, unforeseen operational limitations showed, schedule slips occurred, production quantities changed which served to increase total program costs. That logically led to a longer payback period and fewer modified aircraft.

Conceptually, a B-52 engine replacement can be a low technical risk program. But that does not excuse the USAF from marginalizing the technical risk or the costs involved. It is in this area where the operational impacts will show. As the USAF changes the engine, it also imposes changes on flight dynamics, engine out characteristics, wing flutter, weapons release envelopes, to name a few. The placement of engines on the wing is an issue of concern, as is the design of the engine nacelles. Each of these problems will have to be solved. Each of these solutions will cost money. This money will eat into the proposed ‘savings,’ eroding the true savings of the program. This program is much more complicated than a straight forward plug-and-play engine. Any staff agency or corporation that claims plug-and-play ease is understating the complexity of the problem.

Historically, when an aircraft has undergone a re-engine, the aircraft environment has remained the same before and after. The KC‑135 was an air refueler before it received upgraded engines. After its new engines were installed it did the same mission in the same environment. The B‑52 is a bomber, that has never changed, but the manner and methods the B-52 has used over the years have changed dramatically. A critical example of this fact is how any new engine will affect the B‑52 tail and the rudder.

The Tail.

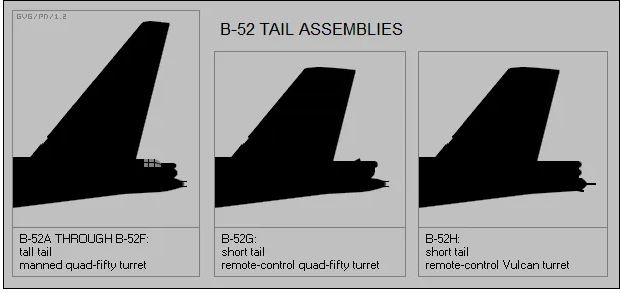

When the B-52 was first designed it was envisioned for high altitude interdiction missions delivering nuclear bombs. The large vertical ‘shark’ tail was designed to optimize the high altitude flight regime. In the 1960s, when the F‑model was redesigned as the G-model, the tail was ‘cut off’ by 8 feet. This was done because the mission of the B‑52 had changed to low level penetration and the larger vertical tail surface was prone to flutter at low altitudes and high speeds. Therefore the tail was shortened and the chord (width) of the tail was increased. This removed some of the vertical surface to reduce the risk of flutter and strengthened the overall structure of the tail. Today the B-52 has reduced its low level mission (anti-shipping and mining operations) and is back to primarily high altitude bombing.

The tail on today's B-52H has a reduced static directional stability than what was originally designed. When the B-52 is in a disturbed condition at a sideslip angle, like when it loses an engine, the fuselage and engines pods are destabilizing, i.e., they work to increase the disturbance. That’s bad. The vertical tail surface counters that by generating a stabilizing side force. The B‑52 has a large fuselage side area, therefore it needed a massive vertical tail surface to counter it and produce a favorable static directional stability. When the tail was chopped, the Buff lost some directional stability in the high altitude regime, notably in air refueling. That directional stability was initially not acceptable and a new yaw dampener had to be designed to compensate.

Look at the situation that the B‑52 currently sits. The size of the tail that was designed for the B‑52A optimized for a specific regime, at a specific thrust range. The tail was reduced in size and the thrust of the engines has increased, making the situation worse. Each modification has exacerbated this situation. The next modification could create unacceptable flight dynamics, causing unprecedented delays as new flight control workarounds are implemented. When thinking about new engines, the vertical tail is not something that can be ignored.

The Rudder

Concerning the rudder, the situation is much worse. The B-52 rudder and elevator have an exceptionally narrow chord. Most airplanes have at least a 25% chord, which allows sufficient power and effectiveness in both yaw and pitch during takeoff, landing, and asymmetric conditions. The same is not true of the B-52 with its 10% chord rudder and elevator. The chord was reduced because original designs of the aircraft had the tail exceeding critical Mach prior to the wing. The chord of the tail was reduced to ensure that the wing reached critical Mach first.

The original designers knew that the rudder was underpowered. An aircraft the size of the B‑52 requires a massive rudder that does not exist. This rudder is insufficient for the basic needs of the aircraft, let alone for asymmetric engine-out scenarios. Original plans called for an all moving vertical tail, the first of its kind. However, Boeing doubted the reliability of the hydraulic actuators necessary to achieve this. The design was also too heavy for the tail structure to sustain. Therefore, Boeing designed, built, and incorporated the yaw-adjustable cross-wind landing gear,what is known to B‑52 aviators as ‘cross-wind crab.’ This system allows the B-52 to operate during normal conditions of take-off and landing in crosswinds. However, the true problem was asymmetry.

Aircraft are most susceptible to asymmetric conditions during takeoff. An engine loss when the airplane is rolling down the runway, accelerating towards takeoff, can be catastrophic. When an engine fails during takeoff, the yawing moment displaces the airplane from the center of the runway. Rudder authority is what keeps the plane on the runway, however rudder effectiveness is dictated by speed. The faster the plane is, the more effective the rudder becomes. The airspeed at which the airplane, after engine failure, deviates 30 feet from the runway centerline, despite using maximum rudder (but without the use of nose wheel steering) is called the Minimum Control speed on the Ground (VMCG). The B-52 rudder is sufficient to handle one engine loss during takeoff only when that failure is within a certain speed range and the failure concerns certain engines. Overall, the B-52 cannot pass this standard without the use of nose wheel steering. The Flight Manual specifically calls for the use of full rudder in any engine out scenario, the failure to do so could result in an increase of minimum control speeds of up to 25 knots. Today’s B‑52 would not pass FAA certifications.

The KC-135 encountered a similar scenario when it upgraded from the TF33 to the CFM56. The newer engine had much more thrust (22,500 pounds) and created a much worse asymmetry during an engine out. The KC-135 had to install an Engine Failure Assist System (EFAS) to help with the situation. The pilot alone could not recognize and compensate fast enough to save the aircraft. The EFAS addition was necessary, was not envisioned at the program start, was not budgeted, and had an adverse effect on overall program success.

If the B-52 is retrofitted with a 4-engine setup, the rudder will not be capable of maintaining control in asymmetric conditions. A 4‑engine B-52 will require a new rudder. While an 8‑engine retrofit would reduce the risk in this area, it would not eliminate the necessity for testing. The thrust range is the particular concern. The 17,000 pounds of thrust of the TF33 is already outside the limits of the rudder. The current B-52 is thrust limited and does not utilize full power. Many new engine programs have dreams of smaller runways, higher temperatures, and greater takeoff weights. These things will not be possible for the B-52. The new engine will most likely have to be de-rated to maintain a margin of safety or have a new rudder system designed. A new rudder would likely be cost prohibitive.

Performance Upgrades.

Just as the DC-8 upgrade showed a decrease in payload and takeoff weight after upgrade, similar issues present when approaching a B‑52 re-engine with the objective of increasing performance.

When Strategic Air Command installed the Electro-Optical Viewing System (EVS) on G and H-model B-52s it created a speed problem. Prior to the EVS modification, the aircraft was capable of 0.91 Mach. The EVS modification created issues with airflow over the nose and between the chin pods. Higher speeds create localized supersonic airflow and made the pitot-static system unreliable. As a result the B‑52 was policy limited from its true top speed to a more reliable airspeed of 0.84 Mach. Therefore, new engines do not represent higher speeds for the B-52. Even if the EVS turrets are removed, it would only allow a return to the true aerodynamic limit of the airframe of 0.91 Mach. This speed is already achievable. Speeds greater than 0.91 Mach are unsafe because the B‑52 has a well-defined Mach Tuck. Higher speeds would require a complete redesign of the entire aerodynamic surface. The B‑52 is aerodynamically speed limited. In the area of speed, new engines accomplish nothing.

Many claim that new engines could increase the B‑52’s payload, allowing it to carry more bombs. Also not true. The B‑52 weapons carriage is volume limited, not weight limited. The only way to get more weapons is to create new racks to maximize the space available in the bomb bay and on the external carriage systems. New engines cannot give the B‑52 more space to carry more bombs.

Others claim a new engine would make the B‑52 more reliable. Again, not true. Hard as it may be to believe, the B‑52 is one of the most reliable aircraft in the USAF inventory. Mission capable rates vary by year, but the B‑52 has not fallen below 70% mission capable for decades, while the B‑1B and B‑2A have never been above 70%. 2016 Mission Capable Rates put the B‑52 at 72%, B‑1B at 46%, and the B‑2A at 55%. Understand, the engines have nothing to do with the mission capable rates of any of these aircraft. The low rates for the B‑1B and B‑2A are not engine related, nor is the high rate for the B‑52. The point is, the B‑52 is already the most reliable bomber the USAF has in its inventory. The limiting factor for all the bombers is electrical and avionics related. There is a case to be made for increasing the reliability of all the bombers, but engines will not increase or decrease that reliability. If there is money to be spent on reliability, that money does not need to be spent on B‑52 engines.

Still others make statements concerning the B‑52’s lifespan and how new engines could let it fly far past 2050. These claims are also false. The limiting factor on the B-52 service life has always been, and remains, the upper wing surface. The B‑52 upper wing surface was designed to give the aircraft a 35,000 hour service life. The reason the H-model B‑52 remains in service today is because it sat alert for decades and did not fly nearly as much as its predecessors. In terms of hours flown, the B‑52 is middle-aged. However, that timeline will have an end state. The current projections of B‑52s flying to 2040 are at current usage rates with current hours on its current wings. If the B‑52 flies past 2050 in bulk, it will need to resurface the wings, new engine or not.

Granted, a new engine can and will increase range and endurance but these performance increases are a by-product of engine efficiency. A program dedicated to increasing these capabilities does not make sense. Some engineering studies have stipulated that better engines could increase the unrefueled range of the B-52 by as much as 45%, however B‑52 range is already the most impressive in the USAF fleet. The B-52 has many problems, however range and endurance are not among them. A program designed to fix non-existent problems does not need to exist.

For these reasons, a B‑52 re-engine program should not strive to increase performance in any way. Performance may increase in some areas, but it should not be the objective of the program. Similarly, fuel savings should not be the objective either. The only objective for a B‑52 re-engine that makes any sense is to reduce overall cost for the USAF.

Cost Savings.

Because of these reasons, the goal of the B-52 re-engine program should be cost savings. The B‑52 does not have a performance problem, nor does it have a fuel problem. The B‑52 does have a cost problem, and that problem is entirely engine related. The TF33 engine, while easy to maintain by maintenance standards, is maintenance intensive. A modern engine would produce a drastic reduction in engine maintenance actions across the spectrum. But even that savings is not good enough. True cost savings exists only when the USAF divests itself of the TF33 engine fleet wide, not just for the B-52 fleet, but for the entire USAF fleet.

The TF33 has undergone an exponential increase in maintenance costs over the years, especially in depot. In FY99 it cost $286,000 to depot overhaul a TF33. Something that had to occur every 1500 hours. The studies done assumed cost to overhaul the engine would remain static with only inflation increases. By FY06 that cost had increased to $1.025M for each engine, much more than the studies had anticipated. By 2040, the projected end of the B‑52 service, it could cost more than $7M to overhaul each TF33. While the B‑52 program maintains 855 TF33 engines, the USAF as a whole cares for 2300 TF33 engines. True cost savings is in removing all of the TF33s. That means a re-engine program for the B-52, E-3, E-8, and OC/WC‑135s and the facilities and programs to maintain those engines.This is where true cost savings will be realized. The USAF must take a holistic re-engining approach towards the TF33 engine with the goal of removing it from the inventory.

Completely removing the TF33 from the inventory is the only way a re-engine program for the B‑52 makes any sense.

Where the B-52 differs the most from all other re-engine programs, military or civilian, is when it comes to resale. The DC-8, 707, KC-135 and others all had residual value when their primary owners were finished with them. Re-sale recouped some of the sunk costs. The resale value of a B‑52 is zero. Not because it has no value, but because it will never be sold. While it is in the US interest to equip allies and friends with military technology, that store does not sell everything. Air superiority, air transport, and air refueling have value to the coalition, and the US wants to equip its allies with these capabilities. However, global strike capabilities are an entirely different story. The ability to strike over intercontinental distances with significant mass is something the US holds dear and does not wish to export. Therefore, all of the cost involved in a B‑52 re-engine and all of the savings must be realized with the primary owner.

The Way Forward.

If the USAF decides to pursue a B-52 engine retrofit it should be done to maximize cost savings at the lowest possible technical risk. To reduce risk in the program, the following recommendations should be implemented:

-

The entire TF33 inventory should be divested. This requires engine retrofits for the B‑52, E‑3, E‑8, OC/WC‑135s. TF33 depot facilities and the programmatic infrastructure supporting such activities should be repurposed or divested. This will increase program and technical risk by including 4 other weapon systems, however, without the other weapon systems the program does not meet its primary goal of cost savings.

-

An 8-engine solution should be implemented. A 4-engine solution introduces unnecessary cost-prohibitive problems with asymmetric conditions and clearance volume under the wing. It also would require a ‘re-plumbing’ of fuel, hydraulic, pneumatic, and electrical systems.

-

A commercial, in-production engine should be selected. This engine will have to be modified for military use, but is still less risky than a completely new source-selected engine.

-

The engine should fit within the available volume of the existing engine nacelles. To design larger nacelles will have an adverse effect on the flight control systems.

-

The engine should be of comparable weight of the existing engine. Too heavy and the wing will suffer structural problems, too light and the wing will experience flutter. An engineering analysis will have to be done to optimize weight tolerance of a new engine.

-

Key Performance Parameters must not be based on performance increases. Any increase in performance will be a by-product of engine efficiency. This program must be viewed as a logistical program, not an operational one.