|

|

|||||||||||

|

Radschool Association Magazine - Vol 43 Page 15 |

|||||||||||

|

Privacy Policy | Editorial Policy | Profit Policy | Join the Association | List of Members | Contact us | Index | Links |

|||||||||||

|

Back Go to page: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Forward |

|||||||||||

|

Operation Talisman Saber.

(There are a lot of photos in this story and it could take a while to load.)

Exercise Talisman Saber (2013) is a biennial combined Australian and United States military training exercise, designed to train our respective military forces in planning and conducting combined operations to improve the combat readiness and interoperability between them. This year it is a US led and Australian supported exercise conducted across a wide spectrum of military activities. It also contributes to the ability of Australian and US forces to work together efficiently and safely. More than 28,000 U.S. service members and Australian Defence Force personnel were involved in the Exercise.

The Exercise was scheduled to take place from 15 July to 5 August 2013 in designated ADF training facilities throughout Queensland and in adjacent maritime areas of the Coral Sea. Key sites include the Shoalwater Bay Training Area (Central Queensland), Townsville Field Training Area and facilities in Brisbane, Gladstone and Alma Ports.

The USAF had several of their heavy aircraft based at Amberley and over the week 22 – 26 July the Aviation Media were invited to the base to meet with and to interview the US and Australian crews, to look over the aircraft and to participate in several of the exercises. We were fortunate enough to be invited along. (You can click a lot of these pics for better resolution)

|

|||||||||||

|

On the Tuesday, (23July) we were met at the gate at Amberley by Paul Lineham, the Regional Manager, Defence Public Affairs - South Qld, fitted out with hi-vis vests and passes and escorted down to the Base’s Air Movements Section for a briefing. If it has been a while since you were on a Base, the change in facilities over the years is quite remarkable, none more so than the Air Movements Section. The old dis-used, out of the way hangars have been replaced by purpose built buildings that would be equally at home at a major civvy airport. Divided into two sections, for arriving and departing passengers, facilities include check in counters, customs facilities, comfortable seats, food and drink vending machines and even luggage carousels. |

|||||||||||

|

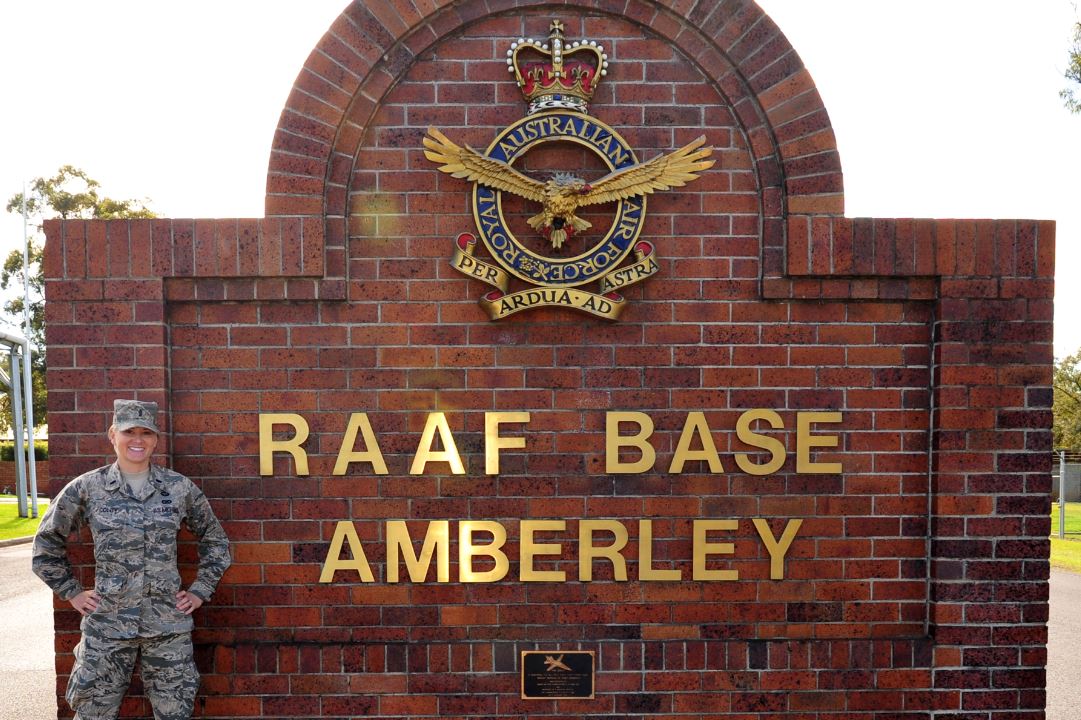

Jessica Colby, (below) a 1st Lieutenant with the USAF briefed us on what to expect over the day and then took us out to have a look over one of the USAF’s KC-135 tanker aircraft.

Jessica joined the USAF in 2004. She attended the United State Air Force Academy from 2007-2011 where she received a Bachelor of Science in English Literature and served as a member of the United States Air Force Parachute Team Wings of Blue. In 2011, she commissioned as a Public Affairs Officer and is currently stationed at Joint Base Pearl Harbor-Hickam, Hawaii on Oahu as the Deputy Chief of Public Affairs at the 15th Wing.

A lovely lady. |

|||||||||||

|

The Boeing KC-135 Stratotanker was built on the Boeing 717 airframe, not, as is often thought, from the (different) B707 airframe. It first flew in 1956 and entered service with the USAF in June 1957. Despite increased maintenance costs, it is thought many of the original 803 aircraft could be flown until 2040. The aircraft will eventually be replaced by the Boeing KC-46 which is based on the Boeing 767.

|

|||||||||||

|

(Above) The interior of the KC-135. Fuel is carried in tanks fitted under the floor while the interior (shown) can be used to carry a mixed load of cargo and passengers.

TSgt Tyler Williams, who operates the refuelling-boom, showed us his cramped and uncomfortable little station from where he works. Situated down the back of the aircraft, under the floor, the boom operator’s station requires the operator to lie on his stomach and look out the small window in the skin of the aircraft and from there steer the boom onto the approaching aircraft.

It’s a bit like a WW2 tail gunner’s platform.

Further info on the KC-135 can be found HERE.

|

|||||||||||

|

We were then loaded onto one of the USAF’s C-17 transport aircraft. Four of these aircraft were to leave Amberley, first was a RAAF aircraft, then us in the USAF aircraft, then another USAF aircraft and last of all another RAAF aircraft. We were to fly to the Shoalwater Bay training area, north east of Rockhampton, (Shoalwater Bay Training Area is one of the largest military training areas in Australia) where all aircraft were to carry out training low-level para drops – and we were invited along.

|

|||||||||||

|

The C-17 is an amazing aircraft. Designed in the US by McDonnell-Douglas and first flown in 1991, the aircraft is now built by Boeing since the merger of the two companies. To date there has been 250 built and it is in service with a number of countries such as the United Kingdom, Canada, Qatar, United Arab Emirates, NATO Heavy Airlift Wing, India and Australia (the RAAF has 6). It is able to carry loads such as:

|

|||||||||||

|

|||||||||||

|

All this

is done with a crew of 3, two pilots and a load-master and it is able to

land the whole lot on 3,500 foot long unprepared strips. Not bad for an

aircraft capable of carrying 77,500 kg. It is able to do this due its

super tough landing gear and a feature called a “Propulsive Lift

System.” The Propulsive Lift System (PLS) uses engine exhaust to

generate lift, the engine exhaust is directed onto large

blown flaps which extend into the exhaust stream, allowing the

aircraft to fly a steep approach at a relatively low speed.

It can arrive at a destination at high altitude, wait until the area below is secured then engage the PLS, point the nose down at a very steep angle and drop slowly onto the landing area, probably very un-nerving if you’re down the back and don’t know what’s going on but perfectly safe and controlled none the less.

The steep approach helps pilots make precision landings with the aircraft touching down precisely in the spot desired on limited runway surfaces. In the flap system, the engine exhaust from pod-mounted engines impacts directly on conventional slotted flaps and is deflected downward to augment the wing lift. This allows aircraft with blown flaps to operate at roughly twice the lift coefficient of that of conventional jet transport aircraft.

From our time with the Caribou and the A-Model Herc, we’d learned to keep an eye on the load master, if he (there were no shes in those days) didn’t look worried then neither should we but if the loady looked worried, it was always best to hang on tight. |

|||||||||||

|

All strapped in and ready to go are L-R: John Sambrooks, secretary of the RTFV-35 Sqn Assoc, John Armstrong, managing editor of Strike Publications and Paul Lineham who gave up his day to escort us and answer a million silly questions we put to him.

|

|||||||||||

|

Pic John Armstrong |

|||||||||||

|

Sqn Ldr Deanna Nott, Director of Communication - Cadet, Reserve and Employer Support Division. (Department of Defence) |

|||||||||||

|

Deanne, who is normally based in Canberra, came along for the ride too, just to make sure we were all on our best behaviour. Deanna started her career as a journalist, and completed her undergraduate degree in Arts at Bond University. She also has a Master of Defence Studies from the University of New South Wales.

She has earned a reputation as a dynamic, enthusiastic and hard-working professional, having expertly handled the public affairs aspects of a wide range of high level Defence events and activities, including rescue missions, natural disaster relief and conferences. Deanna has been involved in many international and Australian military exercises and operations. She is currently Director of Communication for the Department of Defence’s Cadet, Reserve and Employer Support Division and somehow finds time to also be the public affairs officer for the RAAF Amberley Aviation Heritage Museum.

In November 2012 she was awarded an Australian Defence Force Silver Level Commendation for her efforts in promoting the benefits of Reserve service to the Australian community.

Once we were briefed on the aircraft’s safety procedures, it was find a seat, strap in, hang on and off we went. If Mr McDonnell-Douglas had consulted us when he was building his aeroplane we would have suggested a couples of changes, first would be to add a few more windows so passengers could see the outside and secondly to leave out that thing in the roof that screams like a banshee and replace it with a quieter one. The aeroplane is quite noisy and a long trip down the back without either ear plugs or a bottle of Johnny Walker would be quite a strain. |

|||||||||||

|

|

|||||||||||

|

Amanda Helton, a TSgt with the USAF, seated at the loady’s station in the aircraft. The stairs to the left lead to the flight deck.

|

|||||||||||

|

|

|||||||||||

|

Once airborne it was into low gear, drop the back end and straight up to cruising level, then once established, it was just a normal leisurely flight northwards to Shoalwater Bay. On arrival and after a gradual descent we all moved to the rear of the aircraft which was depressurised, we belted in, the ramp and cargo doors were opened and we could all see the good earth again.

Although the aircraft is fitted with one toilet, with a bunch of passengers on board, one just ‘ain’t’ enough and so with necessity being the mother of all invention, a palletised roll-on, roll-off toilet system was invented that can be loaded as and when required.

|

|||||||||||

|

|

|||||||||||

|

And just in case you get confused, there are signs to tell you which is the left toilet and which is the right???

|

|||||||||||

|

Some of the troops on the way to Shoalwater Bay.

|

|||||||||||

|

Anyone who spent time with the US forces in Vietnam, or any other conflict area, knows what a friendly and generous bunch of people they are. The crew aboard the C-17 could not have done enough for us, the head loady, and I think his name was TSgt Josh Watson, took it upon himself to take everyone’s camera onto the top of the toilet for a photo opportunity and then to the rear of the open ramp to take photos for us of the following C-17.

He did that off his own bat, it was definitely not a requirement, but a very generous gesture and I thank him for that!

|

|||||||||||

|

Then it was drop time, the red light came on, then the orange and finally the green and then with the flick of a switch, away went the load. No untying tie-down straps these days, it’s all electric, just one flick and they’re gone!!

|

|||||||||||

|

Going! |

|||||||||||

|

|

|||||||||||

|

Going |

|||||||||||

|

Pic Nigel Pittaway |

|||||||||||

|

|

|||||||||||

|

Gone! |

|||||||||||

|

|

|||||||||||

|

After the load was dropped, the aircraft was cleaned up and we headed for home – though this time the trip was a little different. It was decided to ‘cruise’ back at 300ft AGL, (called tactical flying) which, without windows to give you some sort of reference, can be a bit un-nerving. We found it can be a bit lumpy down that low and climbing up and over stuff without knowing the stuff was coming up or what the ‘stuff’ was made everyone hitch the belt in one notch tighter, it was a bit like riding the Big Dipper wearing a blind-fold – though by applying the “Loady rule” we were assured this was just normal practice.

We can just imagine what 4 giant lumbering C-17 aircraft looked like, hurtling along at 300 knots at only 300 ft above ground. I would have loved to have been on the ground to see it.

On arrival at Amberley, we entered the circuit and turned onto final with a 60 degree bank. Then the aircraft was slammed onto the ground and it felt like all brakes were locked on and all engines were in full reverse because we seemed to stop on a postage stamp.

On the ground the C-17 is capable of performing a 180 degree turn in only 80 ft and a fully loaded aircraft is capable of backing up a 2% slope using engine thrust reversers. A truly remarkable machine.

The RAAF has 6 of these aircraft. The Federal Government announced the purchase of the C-17s in 2006. Prior to this the ADR relied on USAF C-17s or chartered civvy cargo aircraft – not good enough for a modern military. The first 4 were ordered and arrived between December 2006 and March 2008 then in March 2011 a 5th aircraft was ordered and delivered to Amberley in December 2011 and again in March 2012 a 6th was ordered and was delivered to Amberley in November 2012.

With 2 aircraft always in the hangar, either for maintenance or training, the 5th and 6th aircraft effectively doubled the operational availability of the type and it was only fitting that the C-17s were attached to 36 Squadron, the RAAF’s leading heavy lift squadron which blazed the way with the mighty A-Model Hercs all those years ago.

You can see more on the C-17 HERE.

|

|||||||||||

|

Golf is a game invented by the same people who think music comes out of bagpipes. |

|||||||||||

|

|

|||||||||||

|

On the

Thursday, (25July) we were back at Amberley for another ride, this time

though it was a lot earlier in the morning and the flight was to be

compliments of the RAAF. This time |

|||||||||||

|

|

|||||||||||

|

The Boom system, which was developed by the USAF can deliver fuel 3 times faster than the hose and drogue system, which was developed by the US Navy.

The KC-30A has a fuel capacity of more than 100 tonnes, and can remain miles from its home base for up to four hours with 50 tonnes of fuel available to offload. In its transport role, the KC-30A can carry 270 passengers in relative comfort, comes with under-floor cargo compartments and is able to accommodate 34,000kgs of military and civilian cargo pallets and containers.

Being a prime target itself, it carries an electronic warfare self-protection system against threats from surface-to-air missiles.

The RAAF ordered 5 of these aircraft to replace the 4 retired B707 aircraft which Hawker de Havilland had converted to tankers back in 1988. 4 of the new aircraft are already in service at Amberley with a 5th still at the Airbus Military Conversion Centre in Spain undergoing tests. While the under wing pods operate successfully, there is still a problem with the boom which has yet to be rectified (see HERE).

The KC-30 is a relatively new aircraft with Australia being the lead customer so any problems the RAAF experiences with the aircraft are shared with the RAF, the UAE Air Force and the Royal Saudi Air Force who have also ordered the aircraft.

Once again, we were met at the gate at Amberley, this time by Eamon Hamilton who is the Air Lift Group's Public Affairs Officer and is normally based at Richmond. We were then taken to 33 Sqn’s crew room only to be told that unfortunately there was an hour’s delay so it was off to the Base AAFCANS for the morning heart starter cup of coffee. The AAFCANS, (Army, Air Force Canteen Service) which is the replacement for the long gone ASCO canteens, is, I’ve been reliably told, situated close to where the old Amberley Airman’s boozer once stood.

|

|||||||||||

|

The quality and standard of food and drink offered in the AAFCANS as well as the surroundings, would put the old ASCO to shame. What was a surprise though was the number of people in the canteen mid-morning, quietly going about their business, holding group discussions, another obvious change in the culture of the modern Air Force.

Good thing!!!

|

|||||||||||

|

|

|||||||||||

|

After we’d coffeed ourselves, it was back to 33 Sqn’s hangar and onto the aircraft which had been pre-flighted and was ready to go. This is where you experience a huge culture shock, no longer do you have to endure hours strapped to a red canvas side saddle seat, these days it’s like boarding an International Qantas flight, with the only thing missing being the inflight entertainment screens in the back of the seat in front.

|

|||||||||||

|

L-R: Eamon Hamilton, Craig Murray, Aviation photographer, Nigel Pittaway, Aviation photographer and journalist and Mike Yeo, Aviation photographer, originally from Singapore but now based in Melbourne.

John Broughton, in the “Business Class” section.

|

|||||||||||

|

Looking towards the rear of the aircraft in the ‘economy’ section of the aircraft. |

|||||||||||

|

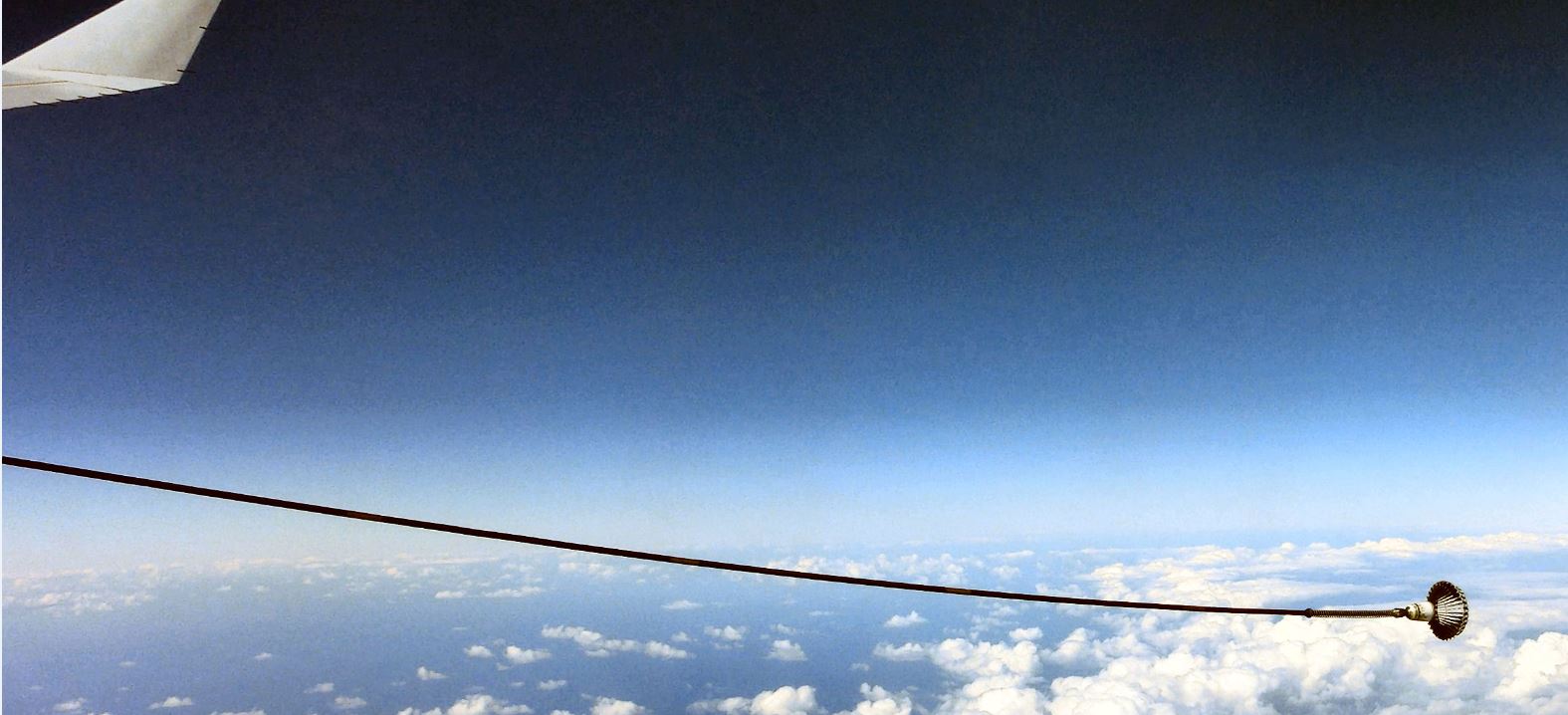

Once airborne, we headed out to sea off Morton Island and eventually the F/A-18s found us and lined up astern. The hoses were run out on each side and the jets lined up to hook up.

|

|||||||||||

|

|

|||||||||||

|

Hooking into those drogues is definitely precision flying, especially in rough weather where the target is swinging all around the sky, though even in clean air, as we had that day, the “bow wave” developed by the receiving jet can and does deflect the drogue just as the jet is about to couple. Watching the coupling you could see the drogue move just as the jet was about to hook up but the F/A-18 boys seemed to have it sorted as there didn’t seem to be a problem. As they say, “Practice makes Perfect.”

|

|||||||||||

|

Once the jets are hooked up, fuel is transferred automatically via the hose and drogue system at the rate of about 1,500 litres per minute then when they were all topped up, they pulled alongside for a photo opportunity then it was a wave from the crew and off they went again.

|

|||||||||||

|

|

|||||||||||

|

Pic Nigel Pittaway |

|||||||||||

|

Click HERE to see a small video of the coupling.

|

|||||||||||

|

The refuelling consoles are situated on the flight deck, behind the pilots, with the two Air Refuelling Operators looking towards the rear of the aircraft. There are two positions, one for each side hose pod with either able to operate the tail boom. A number of cameras, both 2D and 3D are fitted to the aircraft and are displayed on the operators’ consoles. |

|||||||||||

|

When not in use, the hose is reeled in and stored in the wing pods which are situated well out from the engine exhaust. |

|||||||||||

|

|

|||||||||||

|

After the exercise was finished, the hoses were reeled in and we headed for home and luckily for me, just as we hit a bit of turbulence, Jamie Polzin, one of the Cabin Attendants, was there to steady me.

|

|||||||||||

|

|

|||||||||||

|

Jamie has been in the RAAF for 3½ years and before joining 33 Sqn as a Crew Attendant, was in Supply. Prior to obtaining her half wing she had to undergo many weeks of training which included:

|

|||||||||||

|

|||||||||||

|

Jamie has been ‘on the ‘Job’ now since May this year and we asked her whether she liked the job – “JOB??” She says, “this is hardly a job, this is 100% enjoyment” she says "where else could a young girl get a job like this"!!!

She says she couldn’t think of a nicer way to spend the day.

|

|||||||||||

|

We returned to Amberley, had a walk around the aircraft and marvelled at the size of the thing, then it was time to head into Ipswich, frequent one of the locals for lunch and a hold a debrief.

|

|||||||||||

|

Thanks to Paul Lineham, Eamon Hamilton, the crews on both aircraft and MediaOps in Canberra for making it all happen, it was a wonderful experience and was really enjoyed.

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

RAAF Edinburgh

Val Bukmanis |

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

Prior to World War Two, in late 1939 or early 1940, the whole area (where the Base sits today) was compulsorily acquired by the Commonwealth government to build the South Australian Munitions Factory. The factory, beginning production in July 1941, was the largest munitions factory in the Southern Hemisphere and the fourth or fifth largest such factory in the world. The factory manufactured a wide variety of explosives and subsequently manufactured ammunition, detonators, fuses, shells, rockets, mines and torpedoes. At the end of WW II, most of the site was closed down, with the exception of the TNT manufacturing plant (south of today’s RAAF Base) that continued production until the mid 1960s. The plan was to reopen the plant, albeit on a smaller scale, for military and peacetime explosive manufacturing at a later time. This didn’t happen, with most of the operations sold off as scrap with operations being relocated to Gladstone in the mid north of South Australia.

In the 1940s the Anglo-Australian Agreement (the Joint Project) was signed and Salisbury enjoyed a new lease of life. Salisbury housed the administration infrastructure, stores, laboratories and most of the Australian end of the various UK-based contractors. RAAF Edinburgh Field (as it was called in those early days) was the logistics hub plus it housed a wide variety of Royal Air Force personnel. Established in 1953 it was formally opened by HRH Philip, Duke of Edinburgh in 1954. The Base is named after his title. RAAF Edinburgh supported the Salisbury end of weapons trials at Woomera (rockets and missiles) and Maralinga (atomic bomb testing). It had been decided RAAF Mallala was too far away from the Salisbury operations centre to be effective.

The old Tank Farm became the Technical Area; this had to be separate – unlike every other RAAF Base - because of the secret nature of the operations. So it was decided to create a separate Domestic Area in what had been the Cordite Area. Traces of this cordite work can still be seen. The old Airmen’s Mess building (demolished in late 2011) was the Cordite Casting Hall – that’s why it looked like a factory. Similarly, on the southern side of the Base there were two truncated pyramids – these were used for the manufacture of Nitro-glycerine.

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

At

Woomera there were similar, but smaller, arms factories to those set up

at Salisbury, plus the various ranges, trials support test shops and

several airfields. In those early days Edinburgh was very much a

multi-service (RAF and RAAF) establishment. This was necessary to

prepare, fly and service the wide variety of aircraft based there and at

RAAF Woomera. Smaller airfields were established at the Koolymilka

Rangehead (RAAF

Evetts

Additionally, the manned GAF Pika was used to develop the unmanned GAF Jindivik target aircraft. Later, RAF Vickers Valiant, Handley Page Victor and Avro Vulcan aircraft supported the Blue Steel project. Eventually the project wound down, so the area was largely empty.

Headquarters RAAF Edinburgh was formed on 17 January 1955, with an establishment of seven officers and eight airmen. On 23 June 1955 the Royal Air Force Courier Service (Hastings aircraft) moved from Mallala to Edinburgh, and on 28 October the first WRAAF personnel arrived on posting from Mallala. The new Sergeants' Mess was opened on 7 September 1956 while 29 September 1956 saw the first official function in the Officers' Mess. 16 Joint Trials Unit (British Army) disbanded at Weapons Research Establishment, (WRE) Salisbury, on 14 December 1964 and on 14 May 1965, 4 Joint Services Trials Unit disbanded at Edinburgh. Maintenance Squadron Edinburgh disbanded on 1 June 1965 after amalgamation with 2 Air Trials Unit. No 1 Recruit Training Unit commenced training in 1965 and the WRAAF Flight moved from Point Cook to Edinburgh on 15 July 1965 to become part of 1RTU.

Recruit Training Unit stayed at Edinburgh until 2006 prior to relocating to RAAF Wagga. Maritime operations commenced in 1968 with the arrival in Australia of the first three of 11SQN's P-3B Orion maritime patrol aircraft; 11SQN completed their move from RAAF Richmond by June 1968. They were joined, from RAAF Townsville, by 10SQN in 1978 after the squadron commenced operating P-3Cs (replacing the P2V-7/Neptune), the first of which arrived in Australia on 28 May 1978. Air Commodore Ford, on behalf of the Department of Air, officially accepted RAAF Edinburgh from the Director, WRE, acting on behalf of the Department of Supply, on 1 February 1968. A detachment of Aircraft Research and Development Unit (Detachment 'B') was raised at Edinburgh on 15 November 1976 and the unit completed its move from Laverton during February 1977. The School of Aviation Medicine transferred from RAAF Point Cook.

In June 2000, the Australian Government decided to renovate RAAF Base Edinburgh in two stages at a cost of $141.56m. The Finance and Administration Department cited a proposal in June 2000 to redevelop the base.

The Stage 1 redevelopment project, worth $42m began in 2002 to rectify the shortfalls of the previous construction works at the base. Stage 1 was completed in 2004. Works included development of new facilities for ARDU (and demolishing of old buildings), replacement of the hangar workshop, removal of asbestos, renovation of the aircraft shelter, expansion of the ground support equipment storage area, restoration of the armament test support facility and upgrade of site engineering services.

In May 2010 the Australian Government approved $50m in May 2010, from the 2010-2011 budget, for the Stage 2 redevelopment. The project, which cost around $100m, was approved by the Australian Government in December 2008. Stage 2, including construction of permanent facilities for No. 462 and No. 87 Squadrons, new and upgraded facilities (including new crew rooms, a reconfigured briefing room and a common room) for No 92 Wing, new and upgraded facilities for No 24 Squadron, a new air traffic control tower and two ordnance loading aprons, began in late 2009.

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

The 7th Royal Australian Regiment Battle Group commenced relocation from Darwin to new purpose-built facilities (at a cost of about $597.4m) at RAAF Base Edinburgh in January 2011. Over 800 members of the Battle Group are now operating out of the new facilities. Army's presence at Edinburgh consists of the 7RAR mechanised infantry battalion equipped with upgraded M113 Armoured Personnel Carriers, a mechanised combat engineer squadron, a self-propelled artillery battery, a combat services support team and a detachment from the headquarters of the 1st Brigade.

A little known fact about its naming in 1954 may be of interest – and I will stand corrected. It was originally to have an aboriginal name which I cannot remember, but for argument let us call it “RAAF Base xxxx”. As the date for the official unveiling approached, someone in the know pointed out that the name actually meant “Swamp”. “Goodness. We can’t have RAAF Base Swamp . What else can we call it?” “Well the Duke is opening it so why not call it RAAF Base Edinburgh?”

A New plaque was hastily arranged and the ceremony apparently went off without a hitch.

The original plaque?

Well up to the time when I left it adorned the wall in the flight-suit bar just off the main bar in the Officers mess. It was appropriately referred to as................ “The Swamp Bar”.

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

Back Go to page: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Forward | |||||||||||

%20a.jpg)

%20a.jpg)

we were going aloft in one of the RAAF’s new KC-30A Multi Role Tanker

Transports (MRTT), which are operated by 33 Sqn and which are a heavily

modified Airbus A-330. Today we were to refuel a bunch of FA-18s. The

KC-30A is fitted with two forms of air-to-air refuelling systems - an

Aerial Refuelling Boom System (ARBS) mounted on the tail of the

aircraft, (which comprises a 'fly-by-wire' boom refuel system) and a

pair of all-electric refuelling pods underneath each wing. These pods

unreel a hose-and-drogue to refuel probe-equipped aircraft. Both these

systems are controlled by an Air Refuelling Operator who sits in the

cockpit, not down the back as in the KC-135, and who can view the

refuelling process on 2D and 3D screens.

we were going aloft in one of the RAAF’s new KC-30A Multi Role Tanker

Transports (MRTT), which are operated by 33 Sqn and which are a heavily

modified Airbus A-330. Today we were to refuel a bunch of FA-18s. The

KC-30A is fitted with two forms of air-to-air refuelling systems - an

Aerial Refuelling Boom System (ARBS) mounted on the tail of the

aircraft, (which comprises a 'fly-by-wire' boom refuel system) and a

pair of all-electric refuelling pods underneath each wing. These pods

unreel a hose-and-drogue to refuel probe-equipped aircraft. Both these

systems are controlled by an Air Refuelling Operator who sits in the

cockpit, not down the back as in the KC-135, and who can view the

refuelling process on 2D and 3D screens.