| Vol 71 | Page 9 |

Privacy Policy | Editorial Policy | Profit Policy | Join the Association | List of Members | Contact us | Index | Links

Back Go to page: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Forward

Allan George's Gems.

Contents

Can sugar destroy a car's engine

Securing Australia in an age of disruption.

What happens if you use the wrong petrol

Securing Australia in an age of disruption.

Ms Rachel Noble PSM

Director-General, Australian Signals Directorate

The Federal Government has given he Australian Signals Directorate 3 core missions.

-

Generate foreign signals intelligence that gives the Government insight into global strategic and military developments.

-

Protect the nation from cyber threats, from governments, to the private sector small and large and to families and individuals.

-

Conduct cyber offensive operations.

Rachel Nobel, the Director General of the Australian Signals Directorate gave the following speech to the Australian National Security College on the 1st September, 2020.

Can Sugar destroy a Car's Engine?

It's a longstanding legend stretching nearly 70 years. Let's do some mythbusting.

It’s a car culture legend, passed down from generation to generation, that an angry person with a bag of sugar can leave your car dead on its axles. Add sugar to the fuel tank, turn its fuel into a sugary petroleum mess and wait for the owner to start the car and blow the engine.

It’s also a myth.

Sugar doesn’t dissolve in petrol. If you add it to petrol, it just stays in granular form.

“We have not seen an engine damaged or destroyed by sugar in a fuel tank, nor heard of any truly plausible or established cases of this happening,” says Mohammad Fatouraie, manager of engineering at Bosch, one of the auto industry’s main suppliers of fuel system components.

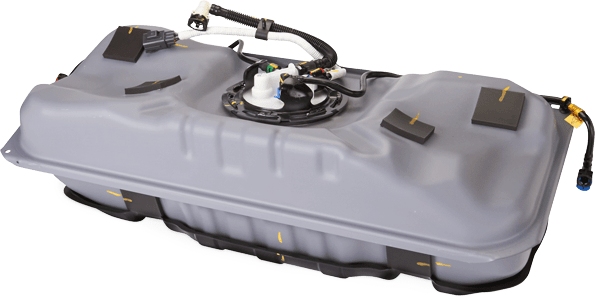

A sugar crystal is about 200 microns. Filters in a car’s fuel system capture particles much smaller than that, so suspended sugar granules in the fuel would be caught by any one of several filters before they ever made it into the engine. There’s a fabric, sock-like filter surrounding the fuel pump pickup in the tank, an in-line fuel filter at the tank pump inlet, a filter on the high-pressure fuel pump in the engine bay and filters at the inlet of each fuel injector.

Even in a carbureted engine, which doesn’t have fuel injectors or their individual filters, there’s a low chance that sugar would ever make it that far into the engine after all the other filters in the system.

Sugar is roughly twice as dense as petrol so some granules wouldn’t even make it all the way to the filters. Particles denser than fuel settle in pockets and corners of low-velocity flow and there are many low-velocity pockets between the fuel tank and the engine. If someone dumped sugar in your tank and you removed the tank to clean it out, you’d see a lot of the sugar granules collected on the bottom. It could clog the in-tank filters and prevent fuel from flowing properly, and while it’s possible that prolonged running of a car with clogged filters could burn out the fuel pump, it’s unlikely to reach that point.

If you knew someone dumped a lot of sugar in your tank, you’d just have to drop the tank to clean it out and replace the sock filter. You may as well test the fuel pump, to be safe and if its flow rate doesn’t match the factory specifications, you’d replace it.

Your engine would be fine – so there you are, but we don’t suggest you try it.

If you shouldn’t be worried about sugar, what should you worry about being added to your tank? Some people say that dumping water into a gas tank would cause the kind of damage that sugar can’t, because engines need their fuel to combust and water prevents that. They’re right, but it’d take much larger quantities of water to do serious damage than an angry car vandal with a bucket could carry.

After all, ever since E10 was mandated, there’s been water in every gallon of fuel you put in your tank. E10 means that 10 percent of every gallon you put in your car is ethanol, a corn-based alcohol fuel that appeared on the market in 2003. Alcohol is very hygroscopic, meaning it absorbs water easily. Moisture-laden air inside the gas tank will pass water into the fuel’s ethanol and so most cars you see on the road today already has some water coursing through their fuel lines. It’s just not enough to cause damage. Even adding water outright to a fuel tank—cue our angry bucket-toting vandal, would cause no harm as long as it doesn’t dilute the fuel so much that there isn’t enough fuel left to combust and power the engine.

It’d just displace some of the liquid fuel in the air/fuel mixture in the engine’s combustion chambers, but oxygen sensors and on-board computers would automatically compensate for the leaner mixture and the engine would run fine without injuring itself.

If the piston can’t complete its stroke in the chamber because there’s so much non-combustible water, the engine becomes hydro-locked. That would cause considerable damage, but under normal situations, the engine would stop operating before failure is catastrophic. Like the sugar myth that inspired it, this myth is also based more on urban-legend.

People often say every myth starts with a grain of truth, but there’s nothing concrete to this one. Early mentions of sugaring someone’s fuel tank to get even with them date from the 1950s. Physics haven’t changed. All it adds up to is a big waste of sugar.

Working from home – but missing the train trips.

After too many beers, my mate asked if he could crash out on my sofa. I had to explain to him that I'm married now, so that's where I sleep.

What happens if you put the wrong type of petrol in your car?

If you drive a lot of different vehicles you have to be careful when it's time to fill them up. Will something happen if you use E10 or 91 instead of 95, or vice versa?

Long story short; there's little to worry about, at least, not when it comes to types of octane. (Putting unleaded into diesel vehicles or vice versa is a different story, of course. This may necessitate you emptying the tank.)

If your car is designed to run on 91 and you accidentally put high-octane in your tank, ultimately, it's nothing serious to worry about. Higher octane fuel does not burn as easily as a lower octane fuel. Higher octane fuels are specified where higher compression ratios are present in an engine, or where forced induction (such as turbo charging) is used. By using higher octane fuel where lower is specified, you will not create a problem with your engine. It does not (by popular belief) add any power to your engine, but will not harm it at all. Worst case scenario is you've just wasted some money by buying the more expensive fuel.

Different fuels burn at different rates, so the spark plug needs to fire at just the right time during the ignition stroke, otherwise you don't burn all the fuel before the valves open, which could cause a backfire (if you're lucky) or could cause your engine to try to turn in the wrong direction (if you're not) because the explosion happens before the crank shaft is in the right position (called pinging), forcing it back instead of over the crest of the revolution. Or it burns too hot and melts a piston. In either case, this will eventually lead to the engine blowing a nice paper currency-sized hole in your wallet.

The spark plug is fired before the piston reaches top dead centre (TDC - upper most position in the cylinder). This allows for the air/fuel explosion time to reach its maximum force by the time the piston is ready to move back down in the cylinder. This may seem weird in the sense that the explosion takes place so quickly, but not if you think about how fast the piston is moving (at 3000 rpm, the ignition fires 25 times per second). As fuel is harder to burn as the octane goes up, it becomes more stable and less likely to burn before it’s supposed to. If lower octane fuel is introduced into an engine that requires 95 or 98, the air/fuel will most likely try to burn before it's supposed to and causing the pre-ignition otherwise known as "ping" or "knock".

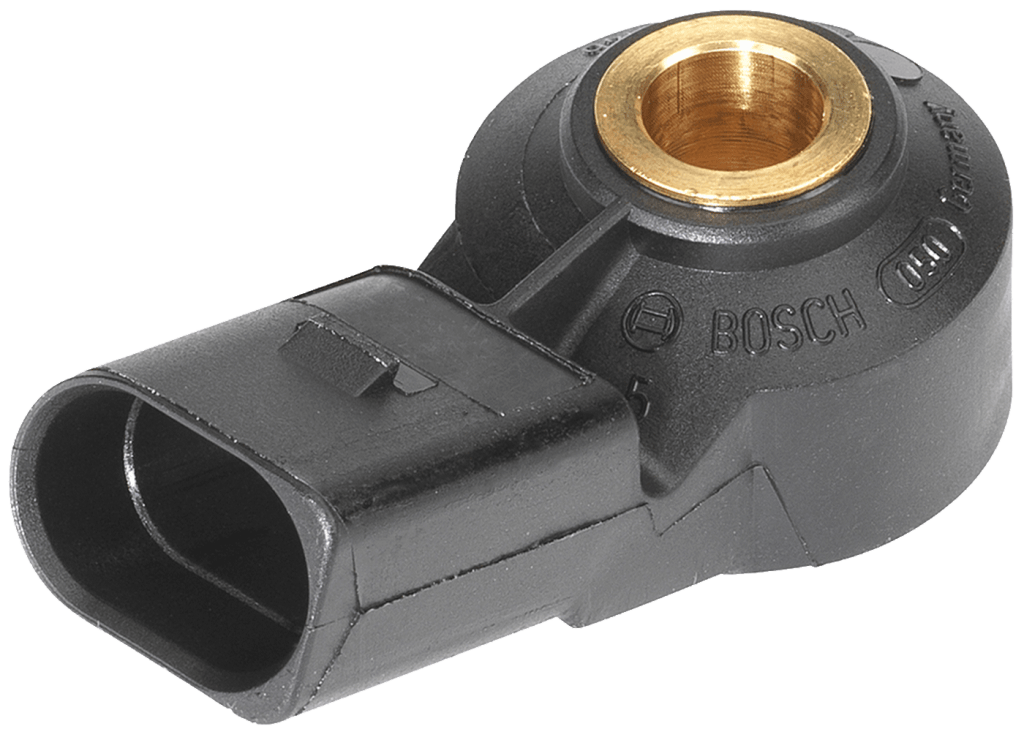

In a modern engine, if you put the lower octane fuel in an engine which specifies high octane fuel, this will not cause you any major issues on an electronic fuel injected engine because it has a device known as a "knock sensor" which will adjust the engine timing. The main effect this has is to reduce the power output of the engine.

Diesel on the other hand should theoretically not ignite in a petrol/gasoline engine because diesel doesn't vaporise very well which is why diesel is ignited by the compression of hot air under extreme pressure. Diesel fuel in a petrol engine can cause flooding of the cylinders and a stall, but in the event that the diesel actually ignites, the most likely scenario is that the engine will run rather rough and sputter a lot before finally dying and flooding, possibly bending or snapping one or more connection rods.

The missus said she's leaving me because I invade her privacy too often.

At least that's what it says in her diary.

![]()

What Is a Knock Sensor?

Have you ever floored the accelerator in your car and heard a slight "knock" or "ping," along with engine noise and the exhaust note? What you're hearing is pre-ignition, which occurs when there's a pocket of fuel/air mixture that's igniting ahead of the flame front from the spark plug. When this happens, there's a tiny shockwave that occurs around that explosion (along with the normal detonation from the spark plug), which greatly increases the pressure in the cylinder. In extreme cases, knocking can result in catastrophic damage to the engine, including cavitation or even perforation of a piston crown.

On an older engine where the ignition timing could be adjusted, knocking could be addressed by retarding the timing a little. Water injection was also a solution at one time and of course, beginning in the 1920s, tetraethyl lead was added to fuel as an anti-knock compound that also protected valve seats.

Leaded gas was outlawed in the mid-'70s and ignition timing on modern engines is dictated by the engine control computer. Older engines advanced or retarded timing via vacuum and would adjust it according to engine load. On a modern engine, the computer receives information from several sensors, but many engines still feature a knock sensor, usually mounted on the intake manifold or cylinder head.

The knock sensor detects vibrations that come from a knock or an irregularity in combustion and send a signal to the engine control computer, which then adjusts timing to correct the knock. Symptoms of a failed knock sensor include:

-

A trouble code will be registered in the car’s computer and the Check Engine lamp (CEL) will come on, although some engines will require multiple failure cycles before storing a code.

-

The engine will misfire

-

Engine vibration, especially at highway speed

-

Thumping or knocking noise from the engine

-

Poor fuel economy and acceleration

Knock sensors don't fail often, but if you suspect this problem, it's one you need to move on quickly to head off engine damage.

Two guys in a health club, one is putting on a pair of women’s lace knickers.

1st guy: "Since when do you wear women's underwear?"

2nd guy: "Since the missus found ‘em in the glove box."

Motor car glut.

If you’ve got a computer and you’ve been on the internet in the past 6 months or so, you’ve more than likely seen this worrying story.

The world’s unsold car stockpile.

Nobody is buying brand new cars anymore!

Well they are, but not on the scale they once were. Millions of brand new unsold cars are just sitting redundant on runways and car parks around the world. There, they stay, slowly deteriorating without being maintained. Below is an image of a massive car park at Swindon, United Kingdom, with thousands upon thousands of unsold cars just sitting there with not a buyer in sight. The car manufacturers have to buy more and more land just to park their cars as they perpetually roll off the production line.

There is proof that the world’s recession is still biting and won’t let go. All around the world there are huge stockpiles of unsold cars and they are being added to every day. They have run out of space to park all of these brand new unsold cars and are having to buy acres and acres of land to store them. It would be fair to say that it is becoming a mechanical epidemic of epic proportions.

If anybody from outer space is reading this webpage, we here on Earth have too many cars, why not come and buy a few hundred thousand of them for your own planet!

The car industry would never sell these cars at massive reductions in their prices to get rid of them, no they still want every buck. If they were to price these cars for a couple of thousand they would sell them, however, nobody would then buy any expensive cars and then they would end up being unsold. Its quite a pickle we have gotten ourselves into. The pic above shows the Nissan test track. Only it is no longer being used, reason...there are too many unsold cars parked up on it! The number of cars keeps on piling up on it until its overflowing. Nissan then acquires more land to park the cars, as they continue to come off the production line.

The car industry cannot stop making new cars because they would have to close their factories and lay off tens of thousands of employees. This would further add to the recession. Also the domino effect would be catastrophic as steel manufactures would not sell their steel. All the tens of thousands of places where car components are made would also be effected, indeed the world could come to a grinding halt.

Below is shown just a small area of a gigantic car park in Spain where tens of thousands of cars just sit and sunbathe all day.

Tens of thousands of cars are still being made every week but hardly any of them are being sold. Nearly every household in developed countries already has a car or even two or three cars parked up on their driveway as it is.

The cycle of buying, using, buying using has been broken, it is now just a case of "using" with no buying.

It is a sorry state of affairs and there is no answer to it, solutions don't exist. the cars just keep on being manufactured and keep on adding to the millions of unsold cars already sitting redundant around the world. As it is, there are more cars than there are people on the planet with an estimated 10 billion roadworthy cars in the world today. We literally cannot make enough of them.

Below are seen just a few of the thousands of Citroen's parked up at Corby in England.

They are being added to daily, imported from France but with nowhere else to go once they arrive. There they sit, brand spanking new cars, all with a couple of miles on the clock that was consummate with them being driven to their car parks. Manufacturing more cars than can be sold is against all logic, logistics and economics but it continues day after day, week after week, month after month, year in year out.

All around the world these cars just keep on piling up, there is no end in sight. The economy shouts out quite loud that nobody has the money anymore to spend on a new car. The reason being that they are making their "old" cars go on a lot longer, but we cannot stop making them, soon we will run out of space to park them. We are nearly running out of space to drive them that's for sure!

Gone are the days when the family would have a new car every year, they are now keeping what they have got. It may be fair to say that some families still get a new car every year but it’s the majority that now do not. The results are in these images, hundreds of thousands if not millions of cars around the world are driven from their factories, parked up and left.

Could we say that these cars have been left to rot! Maybe, as these cars will certainly rot if they are not bought, driven and cared for. It does not look like they will be sold any day soon, many of them have been standing for over 12 months or even longer and this is detrimental to the car. Do you think they will ever start giving them away, that may be the only radical solution. Who knows, you could soon be getting a free car with every packet of cornflakes!.

When a car is left standing idle, all the oil sinks to the bottom of the sump and then corrosion begins to set in on all the internal engine parts where the oil has drained away. Cold corrosion is when condensation builds up in the cylinders and rust forms in the bores. The engines would then start to seize and would need to be professionally freed before they could be started.

Also the tyres start to lose air and the batteries start to go flat, indeed the detrimental list goes on and on.

So the longer they sit there the worse it slowly becomes for them.

What is the answer to this? Well they need to be sold and that just isn't happening.

The epidemic is not improving, it is getting worse. Car manufactures are constantly coming out with new models with the latest technology in them. Hence prospective buyers of, for example, a new Citroen Xsara Picasso want the latest model, not last year’s model.

It’s a great story – but, as usual, it’s all garbage!!

This story started back in May 2014 and photographs referenced above supposedly depict millions of brand new unsold cars, vehicles that are continuously churned out by automobile manufacturers around the world even though there is no demand for them and they end up sitting in car parks “slowly deteriorating without being maintained,” forcing manufacturers to “buy more and more land just to park their cars as they perpetually roll off the production line.” Although the displayed photographs are real, they are several years old (reflecting conditions that existed back in 2009), and do not depict what is claimed in the accompanying text.

One of those photos was taken from a May 2009 article about an Atlanta car dealer noting that in the first four months of that year, 60% of his retail sales profits had come from vehicles that sold for $4500 or less (rather than from new or near-new cars). Another from a January 2009 article about slumping new car sales in the UK and captured a view of some of the thousands of unsold cars that were then being stored at Avonmouth Docks England, while sales of new cars in the UK had slumped to a 12-year-low. Another appears (without additional comment) in a March 2009 Boston.com collection of images reflecting “Scenes from the recession.”

Many of those photographs originated with a January 2009 Getty Images collection titled “Cars Sit Unsold in Avonmouth Docks As Car Sales Stutter” and were also part of a January 2009 Jalopnik article about “Where Are Automakers Stashing Unsold Cars?” and a February 2009 Business Insider article collecting images of “unsold cars around the world,” that latter of which noted that:

Sales of new cars in the UK have slumped to a 12-year-low … the EU’s Industry Commissioner Guenter Verheugen warned the outlook for the European car industry was ‘brutal’ and predicted not all European manufacturers would survive the crisis.

These photographs do for the most part, show unsold automobile inventory in various parts of the world, which hit rather high levels when new car sales badly slumped during the global recession of 2009, but even back then automobile manufacturers weren’t churning out product willy-nilly, regardless of demand — the captions to some of those 2009 photographs in their original contexts noted that, for example, “production of cars at Honda in Swindon has been halted for a unprecedented four-month period because of the collapse in global sales and represents the longest continuous halt in production at any UK car plant.”

Additionally, it isn’t 2009 any more. Although these pictures captured some large overstocks of new cars that were produced just before a huge unanticipated drop in demand, that was a temporary phenomenon from several years ago. British automobile production, for example, rebounded to hit a record high in 2013 (with a car being produced every 20 seconds that year) because UK car sales also reached their highest level in the past several years in 2013, with consumers purchasing a total of 2.26 million vehicles:

UK car sales in 2013 recorded their best year since 2007, industry figures have shown, helped by cheap credit deals and stronger consumer confidence. The Society of Motor Manufacturers and Traders (SMMT) said that 2.26 million vehicles were registered in 2013 which was a 10.8% rise on 2012, although the figure is 6% lower than 2007’s 2.4 million figure. The 2013 total was boosted by a 23.76% rise in sales in December, marking the 22nd successive month of increases.

The Bloomberg news service similarly reported that U.S. auto sales also sharply increased after 2009. If you look for factual data, and you can hunt down a lot of truth with a little bit of effort, beyond the simple tidbit that these photos are more than five years old. For example, we can find how many cars are being sold in the U.S. now, along with plenty of historical data. In 2009, when these photos were taken, U.S. auto sales were running at barely a 9 million annual rate. Fast-forward to today and, as we learned at the beginning of this month, we are running at an annual rate of more than 16 million autos. That is an improvement of 78 percent.

Newly manufactured automobiles are produced according to a schedule based on anticipated demand, and they have to be stored somewhere while awaiting transport to and from ports via truck, ship, or train to dealerships (both within the country of production and abroad). Just because vehicles are temporarily parked en masse for storage purposes doesn’t mean they’re doomed to remain forever unpurchased and sit outside until they deteriorate and are scrapped while manufacturers continue to churn out more and more new cars:

The Avonmouth and Royal Portbury Docks (also known as Bristol Port), a facility shown in many of these photos, handles over 700,000 motor vehicles per year for import, export, and finishing. Given that volume, at any particular time there are likely to be thousands of cars parked there waiting to be loaded (or just having been unloaded) and transported to their final points of sale. Even the text in the “Unsold Cars” article is misleading: According to The Truth About Cars, “Sheerness is one of the leading ports for the importation of cars to the United Kingdom.” The updated photos showing all those cars in the U.K. aren’t unsold inventory waiting to be shipped; they are the precise opposite — these are cars in the pipeline that dealers have ordered, not a vast graveyard of autos waiting to rust.

My mate is thinking about asking his ex-missus to re-marry him,

but he's worried she’ll think he is just after her for his money.

Mirage spy-plane.

On the 7th April, 1983, No 77 Squadron Mirage IIIO A3-57 was flown from Williamtown to undertake a photo reconnaissance mission over the Franklin River in western Tasmania. The distance involved required the pilot to land at Avalon, outside Melbourne, to refuel both before and after crossing Bass Strait to carry out the mission. Within days, the episode became a cause célèbre, after it became public knowledge that the mission had been ordered by Gareth Evans, the Attorney-General in the newly-elected Hawke Labor Government in Canberra.

State Government plans to dam the Franklin for hydro-electricity generation had attracted widespread and vocal opposition across Australia. The new Federal Government directed a cessation of work at the site, and A3-57’s sortie was to ensure that Tasmanian authorities were complying. The affair was a key moment in the history of constitutional relations and environmental protection in Australia.

Gareth Evans was subsequently grilled at the National Press Club in Canberra about this 'operation' and the ensuing Mirage mission in April. His response: "I can best summarise all of this complicated saga by uttering what is known in the profession - or if it isn't known in the profession it ought to be - as the 'streaker's defence'. And it goes something like this: "It seemed, your worship, like a good idea at the time." This phrase entered the political lexicon for some years. Senator Evans also attracted the less-than-flattering nick-name of 'Biggles'.

Woman to husband: "Let's go out and have some fun tonight!”

Husband: "Okay, but if you get home before I do, leave the hall light on."

Aircraft ejection seats.

In aircraft, an ejection seat or ejector seat is a system designed to rescue the pilot or other crew of an aircraft (usually military) in an emergency. In most designs, the seat is propelled out of the aircraft by an explosive charge or rocket motor, carrying the pilot with it. The concept of an ejectable escape crew capsule has also been tried. Once clear of the aircraft, the ejection seat deploys a parachute. Ejection seats are common on certain types of military aircraft.

A bungee-assisted escape from an aircraft took place in 1910. In 1916 Everard Calthrop, an early inventor of parachutes, patented an ejector seat using compressed air. The modern layout for an ejection seat was first proposed by Romanian inventor Anastase Dragomir in the late 1920s. The design featured a parachuted cell (a dischargeable chair from an aircraft or other vehicle). It was successfully tested on 25 August 1929 at the Paris-Orly Airport near Paris and in October 1929 at Băneasa, near Bucharest. Dragomir patented his "catapult-able cockpit" at the French Patent Office.

The design was perfected during World War II. Prior to this, the only means of escape from an incapacitated aircraft was to jump clear ("bail out"), and in many cases this was difficult due to injury, the difficulty of egress from a confined space, g forces, the airflow past the aircraft, and other factors.

The first ejection seats were developed independently during World War II by Heinkel and SAAB. Early models were powered by compressed air and the first aircraft to be fitted with such a system was the Heinkel He 280 prototype jet-engined fighter in 1940. One of the He 280 test pilots, Helmut Schenk, became the first person to escape from a stricken aircraft with an ejection seat on 13 January 1942 after his control surfaces iced up and became inoperative. At 2,400m (7,875ft), Schenk found he had no control, jettisoned his towline, and ejected. The He 280 was never put into production status. The first operational aircraft built anywhere to provide ejection seats for the crew was the Heinkel He 219 Uhu night fighter in 1942.

The Hungarian RMI-8 experimental interceptor fighter had two engines in a push-pull configuration in order to achieve 800 km/h top speed. To save pilots a spring-driven catapult seat was developed but the prototype was destroyed in 1944 during an air raid, shortly before the aircraft’s maiden flight. Another prototype was not finished before the fall of Budapest.

In Sweden, a version using compressed air was tested in 1941. A gunpowder ejection seat was developed by Bofors and tested in 1943 for the Saab 21. The first test in the air was on a Saab 17 on 27 February 1944 and the first real use occurred by Lt. Bengt Johansson on 29 July 1946 after a mid-air collision.

As the first operational military jet in late 1944 to ever feature one, the lightweight Heinkel He 162A Spatz, featured a new type of ejection seat, this time fired by an explosive cartridge. In this system, the seat rode on wheels set between two pipes running up the back of the cockpit. When lowered into position, caps at the top of the seat fitted over the pipes to close them. Cartridges, basically identical to shotgun shells, were placed in the bottom of the pipes, facing upward. When fired, the gases would fill the pipes, "popping" the caps off the end and thereby forcing the seat to ride up the pipes on its wheels and out of the aircraft. By the end of the war, the Dornier Do 335 Pfeil — primarily from it having a rear-mounted engine (of the twin engines powering the design) powering a pusher propeller located at the aft end of the fuselage presenting a hazard to a normal "bailout" escape — and a few late-war prototype aircraft were also fitted with ejection seats.

After World War II, the need for such systems became pressing, as aircraft speeds were getting ever higher and it was not long before the sound barrier was broken. Manual escape at such speeds would be impossible. The United States Army Air Forces experimented with downward-ejecting systems operated by a spring, but it was the work of James Martin and his company Martin-Baker that proved crucial.

Sir James Martin, an Irish immigrant and innovative engineer, began producing aircraft in 1929. He had always had a great desire to invent and make things with his own hands and, by lots of hard work and continuous study, was an accomplished engineer even in his teens.

It was whilst producing the MB1 aircraft (right) that Sir James’ friendship with Capt Valentine Baker was established, giving birth to Martin-Baker Aircraft Company Ltd. Capt Baker’s years of flying experience and incomparable skill was of great importance in the development and flight-testing of the company’s prototypes.

In 1942, during a test flight of the Martin-Baker MB3 prototype, Capt Baker was tragically killed. The engine seized and he was forced to make an emergency landing – the wing tip struck a tree stump, causing the aircraft to cartwheel. His death greatly affected Sir James, who dedicated the rest of his life, and the future of their company, towards pilot safety.

The first live flight test of a Martin-Baker system took place on 24 July 1946, when fitter Bernard Lynch ejected from a Gloster Meteor Mk III. Larry Lambert was the first live U.S. ejectee, he ejected from a Meteor at the Daily Express Air Pageant in 1948. Martin-Baker ejector seats were fitted to prototype and production aircraft from the late 1940s, and the first emergency use of such a seat occurred in 1949 during testing of the jet-powered Armstrong Whitworth A.W.52 experimental flying wing.

Early seats used a solid propellant charge to eject the pilot and seat by igniting the charge inside a telescoping tube attached to the seat. As aircraft speeds increased still further, this method proved inadequate to get the pilot sufficiently clear of the airframe. Increasing the amount of propellant risked damaging the occupant's spine, so experiments with rocket propulsion began. In 1958, the Convair F-102 Delta Dagger was the first aircraft to be fitted with a rocket-propelled seat. Martin-Baker developed a similar design, using multiple rocket units feeding a single nozzle. The greater thrust from this configuration had the advantage of being able to eject the pilot to a safe height even if the aircraft was on or very near the ground.

In the early 1960s, deployment of rocket-powered ejection seats designed for use at supersonic speeds began in such aircraft as the Convair F-106 Delta Dart. Six pilots have ejected at speeds exceeding 700 knots (1,300 km/h). The highest altitude at which a Martin-Baker seat was deployed was 57,000 ft (17,400 m), from a Canberra in 1958. Following an accident on 30 July 1966 in the attempted launch of a D-21 drone, two Lockheed M-21 crew members ejected at Mach 3.25 at an altitude of 80,000 ft (24,000 m). The pilot was recovered successfully, but the launch control officer drowned after a water landing. Despite these records, most ejections occur at fairly low speeds and altitudes, when the pilot can see that there is no hope of regaining aircraft control before impact with the ground.

Late in the Vietnam War, the U.S. Air Force and U.S. Navy became concerned about its pilots ejecting over hostile territory and those pilots either being captured or killed and the losses in men and aircraft in attempts to rescue them. Both services began a program titled Air Crew Escape/Rescue Capability or Aerial Escape and Rescue Capability (AERCAB) ejection seats (both terms have been used by the US military and defence industry), where after the pilot ejected, the ejection seat would fly him to a location far enough away from where he ejected to where he could safely be picked up. A Request for Proposals for concepts for AERCAB ejection seats were issued in the late 1960s. Three companies submitted papers for further development: A Rogallo wing design by Bell Systems; a gyrocopter design by Kaman Aircraft; and a mini-conventional fixed wing aircraft employing a Princeton Wing (i.e. a wing made of flexible material that rolls out and then becomes rigid by means of internal struts or supports etc. deploying) by Fairchild Hiller. All three, after ejection, would be propelled by small turbojet engine developed for target drones. With the exception of the Kaman design, the pilot would still be required to parachute to the ground after reaching a safety-point for rescue. The AERCAB project was terminated in the 1970s with the end of the Vietnam War. The Kaman design, in early 1972, was the only one which was to reach the hardware stage. It came close to being tested with a special landing-gear platform attached to the AERCAB ejection seat for first-stage ground take offs and landings with a test pilot.

With a history spanning over 80 years, Martin-Baker is still run by the late Sir James Martin’s descendants to this day. From that day until now, Martin-Baker has saved the lives of more than 7,500 aircrew members.

See the timeline HERE

My missus left me for another bloke. All that lies ahead now is a miserable, pointless life, with suicide seemingly the only way out.

And while the poor bugger's going through all that, I'll be down at the pub with my mates every night!

On the 31st March 1921, the Australian Air Corps (AAC) – a temporary Army unit raised 15 months earlier – was disbanded and replaced by the Australian Air Force (AAF) as a separate service. Although the Australian Flying Corps (AFC) was disbanded after WW I ended in 1918, Australia was committed to retaining a military air service. Britain had gifted 128 surplus aircraft to Australia to establish an air force, and some of these planes - along with training machines already at Point Cook - were operated by an interim army unit, the Australian Air Corps, during 1920-21.

The AAF immediately took possession of existing aircraft and equipment at Point Cook, Victoria, but not all the AAC’s personnel were transferred across. At its formation the new Service had 21 officers and 128 other ranks, and even six months later this strength had barely doubled. The 153 aircraft which initially came into the AAF’s possession were mainly war surplus machines received under an ‘Imperial Gift’ arrangement.

Most stayed in storage, and for several years only 50–60 aircraft were actually in use. Economies imposed in 1922 forced the RAAF to cut back on development plans, so that even after five years in existence it had less than 700 personnel.

The Commonwealth Gazette of 31 March 1921 announced the formation of the Australian Air Force. The prefix Royal was granted soon after and promulgated on 31 August 1921. Financial restrictions held back the formation of the Reserve elements for some time, even after approval was granted in November 1921. By sheer hard work and determination, the reserve elements of the permanent squadrons came into being and in April 1936 several autonomous Citizen Air Force Units were raised in the major cities of the east coast and in Perth.

The RAAF was the second independent air force in the world, established three years after the Royal Air Force in Britain.

Intelesting - but stoopid!!

Back Go to page: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Forward